毕业设计辅助工具_免费论文文案文章修改神器_毕业设计辅助软件_论文查重...¥0

毕业设计辅助工具_免费论文文案文章修改神器_毕业设计辅助软件_论文查重...¥0 solidworks2018 中文版¥0

solidworks2018 中文版¥0 CA6140车床拨叉831006零件夹具设计说明书——9页...¥0

CA6140车床拨叉831006零件夹具设计说明书——9页...¥0 机械设计制造及其自动化毕业设计(论文)开题报告...¥0

机械设计制造及其自动化毕业设计(论文)开题报告...¥0 XX大学理工类毕业设计(论文)开题报告——自行车配件管理系统...¥0

XX大学理工类毕业设计(论文)开题报告——自行车配件管理系统...¥0 课程设计 CA6140车床拨叉831002的加工工艺及钻φ25孔的钻床...¥0

课程设计 CA6140车床拨叉831002的加工工艺及钻φ25孔的钻床...¥0 补价¥1.00

补价¥1.00 毕业设计辅助工具_免费在线论文文案文章修改神器_毕业设计辅助软件_AI...¥0

毕业设计辅助工具_免费在线论文文案文章修改神器_毕业设计辅助软件_AI...¥0 六自由度工业机器人设计【说明书(论文)+CAD图纸+SolidWork...¥45.00

六自由度工业机器人设计【说明书(论文)+CAD图纸+SolidWork...¥45.00 陈家沟桥梁施工组织设计方案.doc...¥0

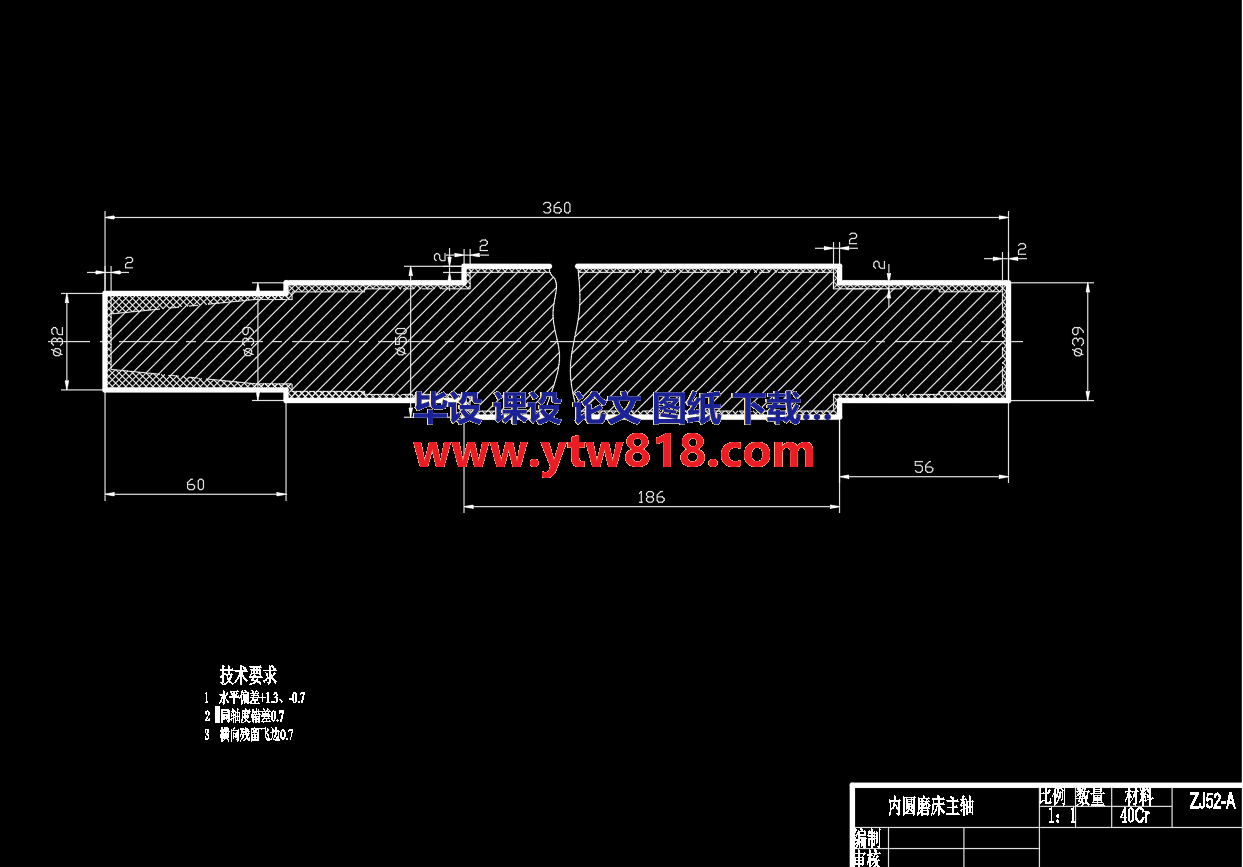

陈家沟桥梁施工组织设计方案.doc...¥0电主轴是加工机床的核心部件,它的精度直接决定了整个机床的加工精度,因此,开发出一个拥有自主产权的高精密电主轴是机械行业的迫切需求。

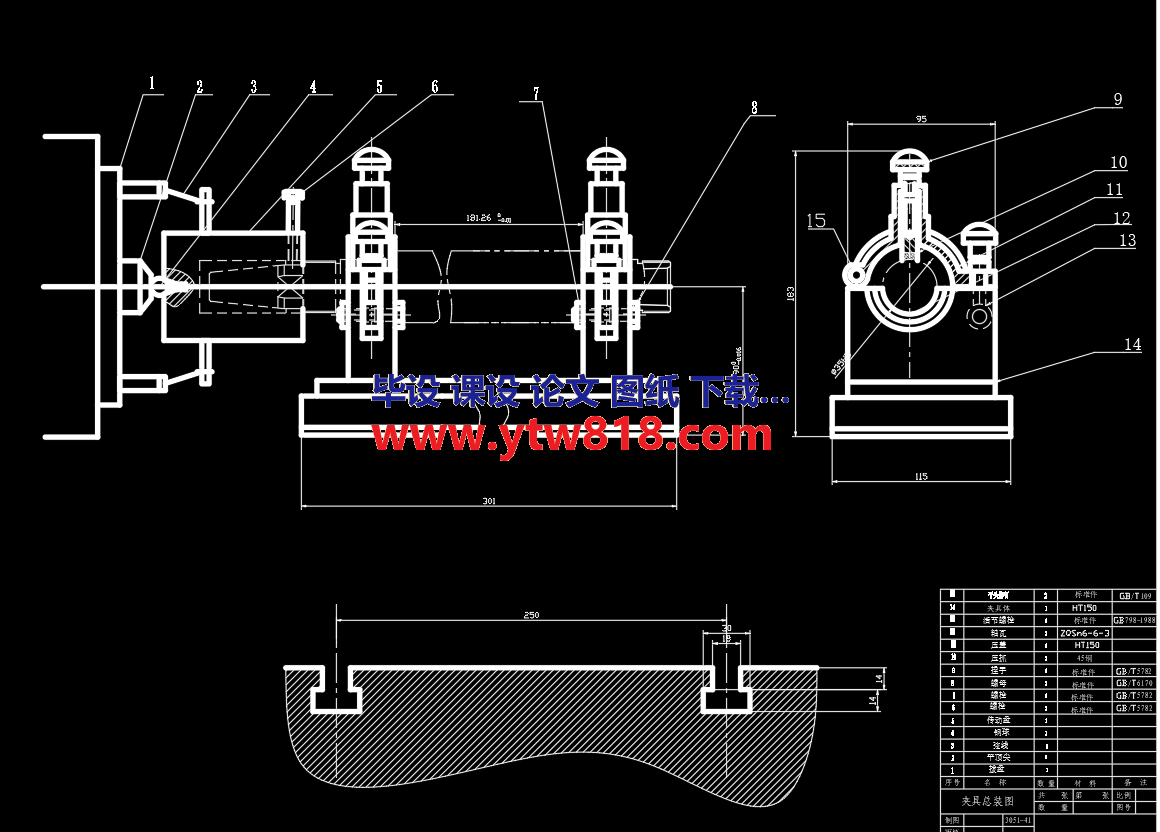

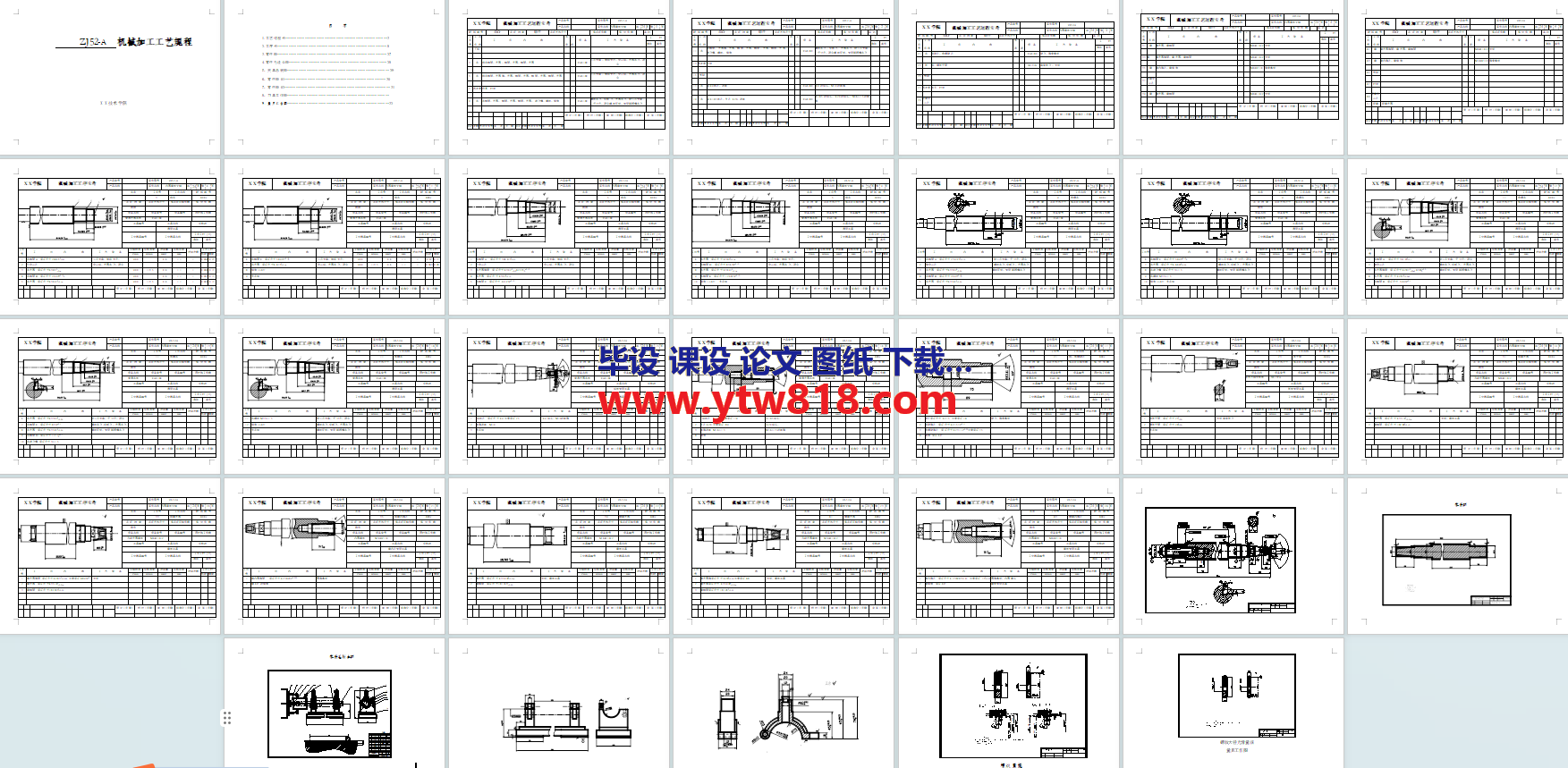

针对这一需要,本文从以下几个方面去设计的:在电主轴的结构上运用最佳跨距计算方法,做出轴的最合理的结构;在布局上采用比较流行的内置电机,循环油冷却系统,角接触混合陶瓷球轴承,油润滑,弹簧预紧的典型形式。结构紧促缩小了主轴系统占用的空间,循环油冷却系统保证了主轴和轴承运转过程中产生的热量很快散出去,油润滑在带走轴承产生的热量同时对轴承进行了润滑;在装配上,严格要求各个环节的精度,尤其在轴承的装配上,根据实测值,采用选配法,保证了整个系统的精度;在电主轴的性能分析上,通过定量去分析电主轴的稳定性,定性去分析其动态平衡性和热稳定性,并加入了仿真分析。

所设计的电主轴,减少了中间传动环节,因此使机床的结构空间减小,同时它比传统内圆磨床转速更高,能耗更小,且传动更加平稳,因此加工精度更高,在保证加工质量的同时提高了效率。

关键词:电主轴 角接触混合陶瓷球轴承 油润滑 仿真分析

Electro-spindle is the core component of machine tools, its accuracy directly determines the machining accuracy of the machine, and therefore, developing their own property rights in a high-precision electro-spindle is an urgent demand for machinery industry.

In response to this need, this paper contains the following aspects: in the structure of the spindle span, the best use of the method of calculating the shaft to make the most reasonable structure; in the layout , use the more popular of the built-in motor, cycle water cooling systems, hybrid ceramic angular contact ball bearings, oil mist lubrication, as well as spring preload of the typical form of rolling sleeve. The urgent structure reduces the space occupied by the spindle system. Circulating water cooling system to ensure the heat generated by the spindle and bearing scatter out quickly mist lubrication scatter out the heat generated by the bearings at the same time lubricate the bearings. so that when temperature rise ,the rolling Introduction sets make the elongation of axis do not affect the precision; in the assembly, the strict demands on the accuracy of all aspects, especially in the bearing assembly on the basis of measured values, using selective assembly method, to ensure the accuracy of the whole system ;in capability of analysis of the spindle, through quantitative analysis of the stability of electro-spindle, qualitative analysis of its thermal stability and dynamic balance;

The designed Spindle motor reduce the transmission link in the middle, thus reducing the machine tool structure of space, while at the same time than the traditional high speed grinder, a smaller energy consumption, and the drive is more stable, so its machining accuracy is higher, and it improve the quality of machining and processing efficiency.

Key words:electro-spindle hybrid ceramic angular contact ball bearings oil lubrication Micro-Milling Machine

4.3电主轴单元静力分析模型简化、单元类型选择、建模与网格划分

……