毕业设计辅助工具_免费论文文案文章修改神器_毕业设计辅助软件_论文查重...¥0

毕业设计辅助工具_免费论文文案文章修改神器_毕业设计辅助软件_论文查重...¥0 solidworks2018 中文版¥0

solidworks2018 中文版¥0 CA6140车床拨叉831006零件夹具设计说明书——9页...¥0

CA6140车床拨叉831006零件夹具设计说明书——9页...¥0 机械设计制造及其自动化毕业设计(论文)开题报告...¥0

机械设计制造及其自动化毕业设计(论文)开题报告...¥0 XX大学理工类毕业设计(论文)开题报告——自行车配件管理系统...¥0

XX大学理工类毕业设计(论文)开题报告——自行车配件管理系统...¥0 课程设计 CA6140车床拨叉831002的加工工艺及钻φ25孔的钻床...¥0

课程设计 CA6140车床拨叉831002的加工工艺及钻φ25孔的钻床...¥0 补价¥1.00

补价¥1.00 毕业设计辅助工具_免费在线论文文案文章修改神器_毕业设计辅助软件_AI...¥0

毕业设计辅助工具_免费在线论文文案文章修改神器_毕业设计辅助软件_AI...¥0 六自由度工业机器人设计【说明书(论文)+CAD图纸+SolidWork...¥45.00

六自由度工业机器人设计【说明书(论文)+CAD图纸+SolidWork...¥45.00 陈家沟桥梁施工组织设计方案.doc...¥0

陈家沟桥梁施工组织设计方案.doc...¥0针对大多数企业,具有数量众多和较长使用寿命的普通机床,其加工精度较低,不能批量生产,自动化程度不高,适应性差,但考虑投资成本,产业的连续性,又不能马上被淘汰。

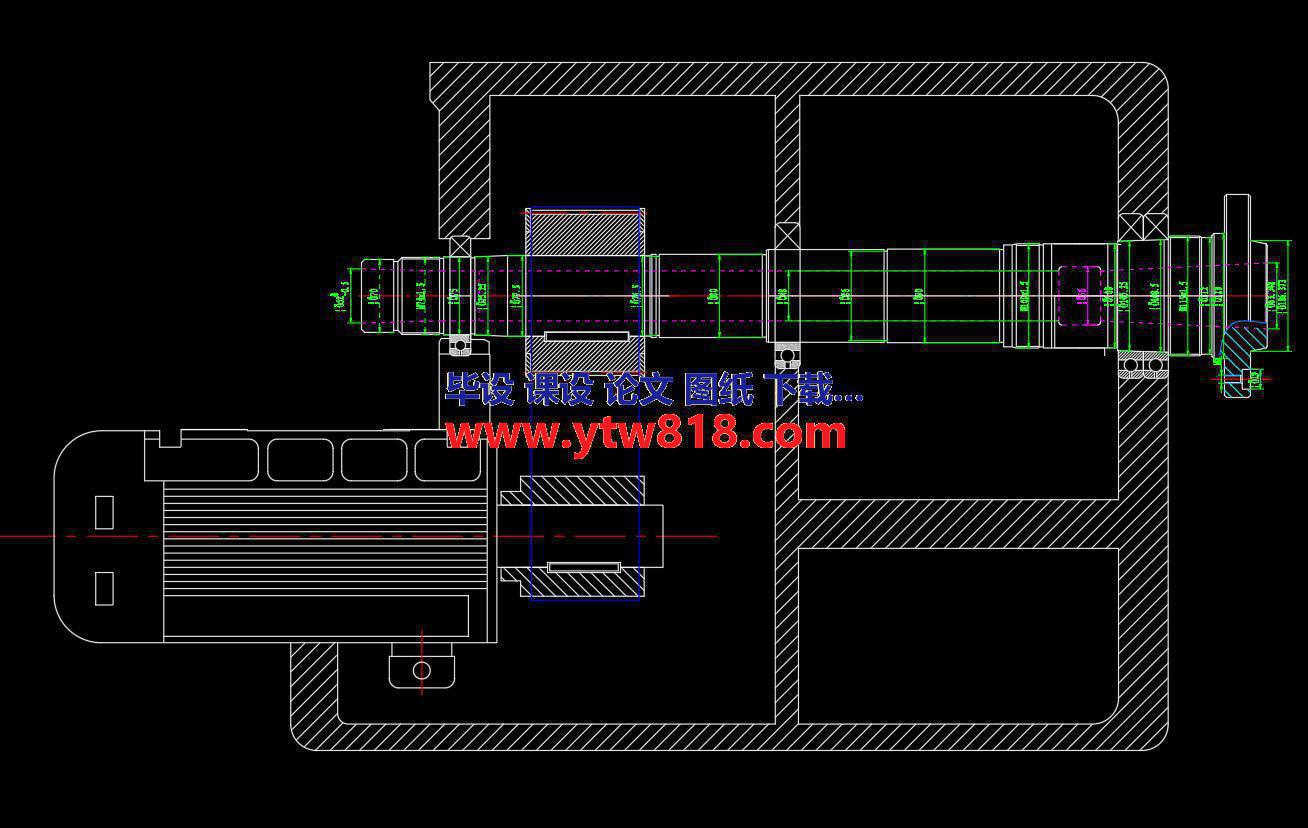

购买新的数控机床是提高产品质量效率的重要途径,但成本高,许多企业在短期内无法实现,这严重阻碍企业设备更新的步伐。为此把普通车床数控化改造,不失为一条投资少,提高产品质量和生产效率的的捷径,提升企业竞争力,在我国成为制造强国的进程中占有一席之地。 本文以普通车床CA6140数控化改造为例,从普通车床改造的经济性进行评价入手,对数控技术在普通车床CA6140数控化改造应用作了深入研究和探索,形成相应的技术方案及要点。主要内容:

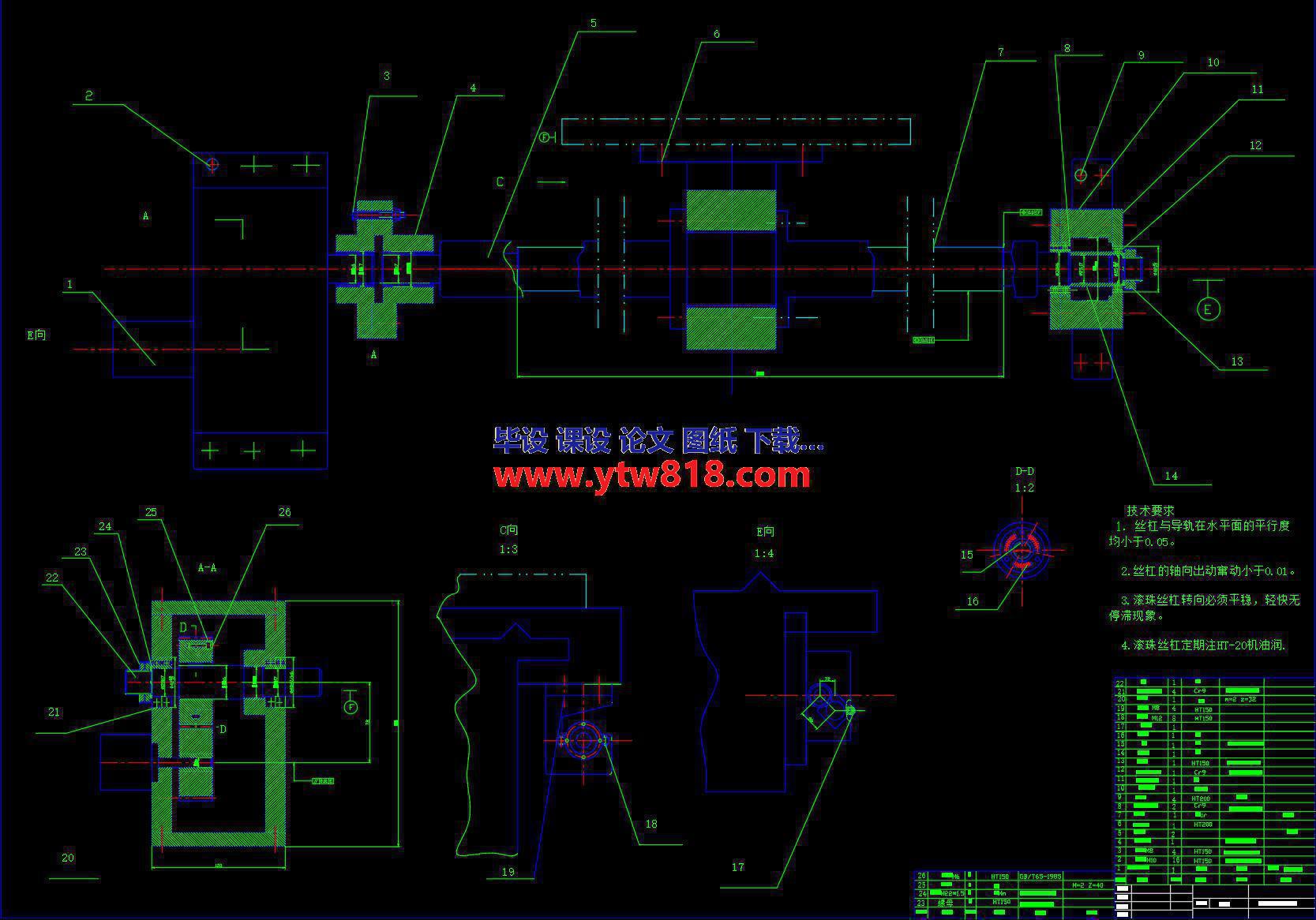

(1) 对普通车床数控化改造经济性评价详细论证,应用模糊优化设计中综合评判原理,确定普通车床数控化改造方案; (2) 对进给系统的滚珠丝杠型号选择与装配设计,支承方式的设计与轴承型号的选择,步进电机的选择等进行详细研究; (3) 对常用进口数控装置系统和国产数控装置系统进行仔细比较,根据所改造的性能和精度指标来选择数控装置系统和自动刀架型号,提出选择方法;

(4) 根据普通车床CA6140电气控制系统和原理图与普通车床数控化改造的数控系统对比分析,形成普通车床数控化改造完整的电气控制技术方案;

(5) 为保持切削螺纹的功能,仔细研究在主轴上脉冲发生器的选型,脉冲发生器直接与主轴间的连接方法,形成相应技术图;

(6) 给出普通车床数控化改造的安装及调试方法。 关键词:普通车床; 数控改造; 伺服系统; 数控系统

NC lathe CA6140 common Abstract

Most enterprises still have large amounts general-purpose machine tools which have longevity of service, low precision, can not adapt to mass productino,low automatization and adaptability,but can not be washed out because of its low cost and continuity of enterprise'sproductino.

Purchasing new numerically controlled machines is an important way to improve production precision and efficiency, but it may not come true to many enterptises because it cost much. Enterprise's equipment updating step are counteracted severly. So General lathe's numerically controlled reforming is a quick way that costs less, improve production precision and efficiency, and it can improve enterprises' competitive power. So it can takes its place in our way to a powerful manufacturing country. The economical efficiency of the reform and the application of NC technology in General purpose lathe CA6140's numerically controlled reforming is researched in this paper according to our practice of CA6140's numerically controlled reforming. And the reforming scheme and main points are formed. The main contents is: (1) The economical efficiency of the reform is evaluated in detail and the rerorming scheme is maked according to misty optimum's synthesize adjudicate principle. (2) The ball screw's type, assembling, supporting, bearing type, and stepping motor of feeding system is designed. (3) The import and domestic NC systems were compared carefully, brought up a choose method and selected the NC system and automatic tool rest according to the function and accuracy index of reforming. (4) The complete electricity control diagram was drawn out according to the result of comparing CA6140's electricity control system. (5) In order to protect the function of cutting a screw, we carefully studied the impulse regulator and its connection with the principal axis, and draw out a technique diagram. (6) Methods of installing and testing of general purpose lathe's numerically controlled reforming were put forward. Key words: General purpose lathe; NC reform; Servo system; CNC system

目 录

Abstract

第1章 绪 论 1

4.2.2 纵向滚珠丝杠螺母副的副的型号选择雨校核步骤 23

5.1.4 据步进电机的矩频特性计算加减速时间校核的快速性 39

…………