毕业设计辅助工具_免费论文文案文章修改神器_毕业设计辅助软件_论文查重...¥0

毕业设计辅助工具_免费论文文案文章修改神器_毕业设计辅助软件_论文查重...¥0 solidworks2018 中文版¥0

solidworks2018 中文版¥0 CA6140车床拨叉831006零件夹具设计说明书——9页...¥0

CA6140车床拨叉831006零件夹具设计说明书——9页...¥0 机械设计制造及其自动化毕业设计(论文)开题报告...¥0

机械设计制造及其自动化毕业设计(论文)开题报告...¥0 XX大学理工类毕业设计(论文)开题报告——自行车配件管理系统...¥0

XX大学理工类毕业设计(论文)开题报告——自行车配件管理系统...¥0 课程设计 CA6140车床拨叉831002的加工工艺及钻φ25孔的钻床...¥0

课程设计 CA6140车床拨叉831002的加工工艺及钻φ25孔的钻床...¥0 补价¥1.00

补价¥1.00 毕业设计辅助工具_免费在线论文文案文章修改神器_毕业设计辅助软件_AI...¥0

毕业设计辅助工具_免费在线论文文案文章修改神器_毕业设计辅助软件_AI...¥0 六自由度工业机器人设计【说明书(论文)+CAD图纸+SolidWork...¥45.00

六自由度工业机器人设计【说明书(论文)+CAD图纸+SolidWork...¥45.00 陈家沟桥梁施工组织设计方案.doc...¥0

陈家沟桥梁施工组织设计方案.doc...¥0摘 要

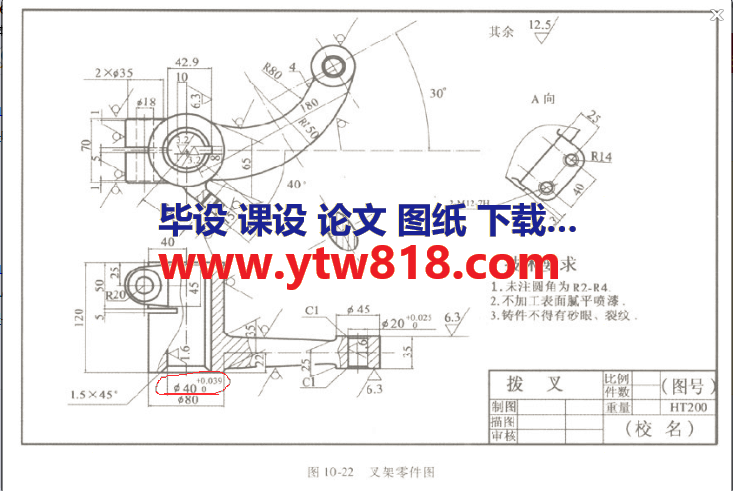

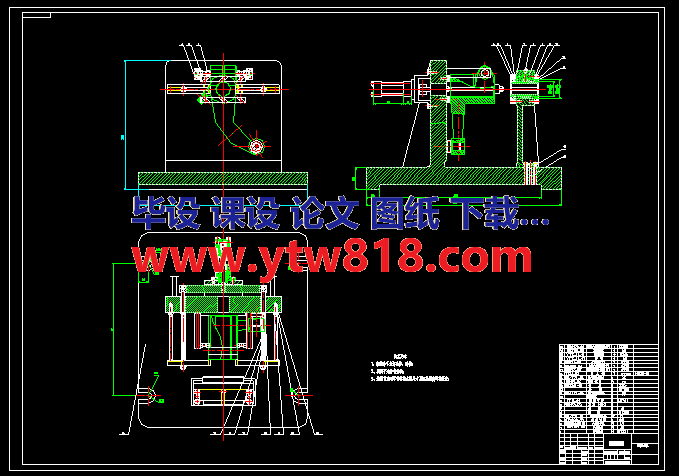

拨叉零件首先对零件进行分析,了解零件的工艺再设计出毛坯的结构,并选择好零件的加工基准,设计出零件的工艺路线;接着对零件各个工步的工序进行尺寸计算,关键是决定出各个工序的工艺装备及切削用量;然后进行专用夹具的设计,选择设计出夹具的各个组成部件,如定位元件、夹紧元件、引导元件、夹具体与机床的连接部件以及其它部件;计算出夹具定位时产生的定位误差,分析夹具结构的合理性与不足之处,并在以后设计中注意改进。

进行专用夹具的设计,选择设计出夹具的各个组成部件,如定位元件、夹紧元件、引导元件、夹具体与机床的连接部件以及其它部件;计算出夹具定位时产生的定位误差,分析夹具结构的合理性与不足之处,并在以后设计中注意改进。

为了防止零件在夹紧过程中变形,保证加工过程中定位的稳定性,则采用钩形压板为夹紧元件对零件底座进行夹紧。为了保证有足够的夹紧力,动力源装置采用钩形压板。

本夹具设计的优点有:结构简单实用、安装方便、易更换、造价低廉。

关键词:夹具,镗孔,钩形压板

Abstract

The fork part first carries on the analysis to the components, understand the parts of the process and then design a blank structure, and choose the good components the processing datum, designs the process routes of the parts; then the parts of each labor step process is the key to decide the size calculation, process equipment and cutting processes; then design special fixture, the fixture selection for the various components of the design, such as connecting parts positioning elements and clamping elements, guide element, fixture and machine tool and other components; calculate fixture positioning errors when positioning, analysis the rationality and shortcoming of fixture structure, improve and design in later.

Design of special fixture, the fixture selection for the various components of the design, such as connecting parts positioning elements and clamping elements, guide element, fixture and machine tool and other components; calculate fixture positioning errors when positioning, analysis the rationality and shortcoming of fixture structure, improve and design in later.

In order to prevent the deformation of the parts in the clamping process, ensure the stability of positioning in the processing process, using the hook clamp for clamping elements for clamping of the base parts. In order to ensure a sufficient clamping force, the power source device adopts the hook clamp.

The advantages of fixture design are: simple structure, convenient installation, low cost, easy replacement.

Keywords: fixture, boring, hook plate

目 录

…………