毕业设计辅助工具_免费论文文案文章修改神器_毕业设计辅助软件_论文查重...¥0

毕业设计辅助工具_免费论文文案文章修改神器_毕业设计辅助软件_论文查重...¥0 solidworks2018 中文版¥0

solidworks2018 中文版¥0 CA6140车床拨叉831006零件夹具设计说明书——9页...¥0

CA6140车床拨叉831006零件夹具设计说明书——9页...¥0 机械设计制造及其自动化毕业设计(论文)开题报告...¥0

机械设计制造及其自动化毕业设计(论文)开题报告...¥0 XX大学理工类毕业设计(论文)开题报告——自行车配件管理系统...¥0

XX大学理工类毕业设计(论文)开题报告——自行车配件管理系统...¥0 课程设计 CA6140车床拨叉831002的加工工艺及钻φ25孔的钻床...¥0

课程设计 CA6140车床拨叉831002的加工工艺及钻φ25孔的钻床...¥0 补价¥1.00

补价¥1.00 毕业设计辅助工具_免费在线论文文案文章修改神器_毕业设计辅助软件_AI...¥0

毕业设计辅助工具_免费在线论文文案文章修改神器_毕业设计辅助软件_AI...¥0 六自由度工业机器人设计【说明书(论文)+CAD图纸+SolidWork...¥45.00

六自由度工业机器人设计【说明书(论文)+CAD图纸+SolidWork...¥45.00 陈家沟桥梁施工组织设计方案.doc...¥0

陈家沟桥梁施工组织设计方案.doc...¥0摘 要

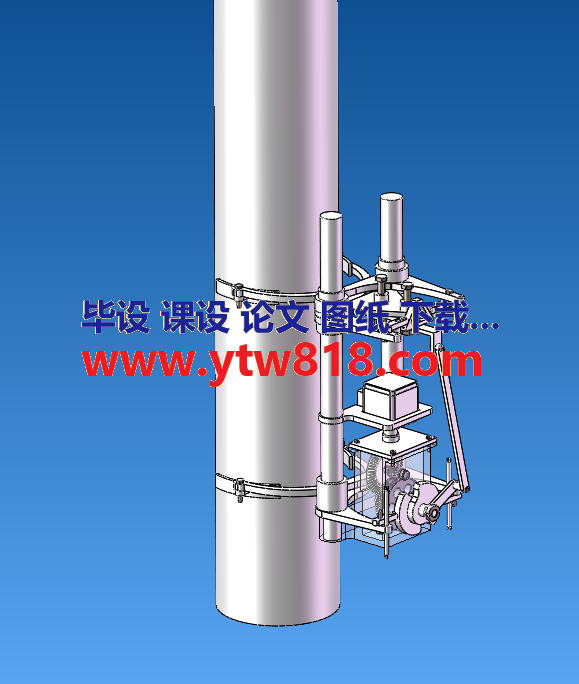

在一些工程类建筑中,一些直径比较小的直杆随处可见,对于这些直杆作业一直存在着一些问题,人为作业较为困难和危险。设计一个可攀爬直杆的机器人,通过该机器人平台搭载一些作业机器,对于解决小直杆的作业问题具有较大现实意义。

本次设计的攀爬机器人是由众多简易的机构组成,在结构上面比较简单,利用我们平时生活中随处可见的曲柄滑块机构、凸轮机构等等结合而成。利用凸轮结构的运动特性实现手爪的夹紧与松开,在驱动源方面只采用一个轻质电机,避免电机过多造成结构上的繁琐和避免重量过重。机械手的手爪采用的是弹簧夹紧的原理,弹簧提供的力足够支撑整个机器人的自重和负重。通过弹簧解决了在变直径杆上攀爬的问题。

本文对曲柄滑块的运动和受力分析证明了该机器人运动的稳定性和可靠性。还通过减速箱的设计赋予机器人一定的攀爬运动速度。还对手爪、轴、轴承等部件的受力校核证明该机器人在结构上面的稳定性。该机器人还具有一定的负重能力。可以在机器人上面搭载一些作业机器人,实现多功能作业。本次设计的机器人通过各机构联动工作,工作简单可靠。

本文还对输出轴的尺寸、配合进行了说明。对轴的加工工艺进行了工艺规程制定,分析各工序的制定方法。对于轴类零件的加工工序有一定的了解与掌握。

关键词:爬杆机器人;变直径杆;夹紧;曲柄滑块

Abstract

In some of the engineering building, a number of relatively small diameter straight bar everywhere, straight bar for these jobs, there has been some problems, man-made work more difficult and dangerous. Design a robot can climb straight bar, equipped with some of the work machine by the robot platform for solving the problems of small jobs straight bar has a larger significance.

The climbing robot designed by many simple bodies, in the above structure is relatively simple, we usually use slider-crank mechanism life everywhere, the cam mechanism, and so a combination. Using the motion characteristics of the cam mechanism to achieve clamping and release the gripper, in terms of the driving source using only a lightweight damping motor to avoid the motor caused by excessive red tape and avoid excessive weight on the structure. Robot gripper uses the principle of a spring clamp, the spring force provided enough to support its own weight and the weight of the whole robot. By spring solves the problem of variable diameter pole climbing.

In this paper, the crank-slider motion and stress analysis to prove the stability and reliability of the robot movement. Also gives some climbing robot movement speed by gearbox design. Also force the opponent claw, shafts, bearings and other parts of the check show that the stability of the structure above the robot. The robot also has a certain weight-bearing capacity. Some jobs may be mounted on top of the robot in robot to achieve mufti-functional operations. The robot design work through the linkage mechanism, work is simple and reliable.

This paper also the size of the output shaft, with the described. Axis machining process were to develop process planning, analysis of the development method in each step. For shaft machining operations have a certain understanding and grasp.

According to the axis of the development process card. Reasonable and feasible production process planning.

Keywords: pole-climbing robots; variable diameter rod; clamp; crank-slider

目 录

…………