毕业设计辅助工具_免费论文文案文章修改神器_毕业设计辅助软件_论文查重...¥0

毕业设计辅助工具_免费论文文案文章修改神器_毕业设计辅助软件_论文查重...¥0 solidworks2018 中文版¥0

solidworks2018 中文版¥0 CA6140车床拨叉831006零件夹具设计说明书——9页...¥0

CA6140车床拨叉831006零件夹具设计说明书——9页...¥0 机械设计制造及其自动化毕业设计(论文)开题报告...¥0

机械设计制造及其自动化毕业设计(论文)开题报告...¥0 XX大学理工类毕业设计(论文)开题报告——自行车配件管理系统...¥0

XX大学理工类毕业设计(论文)开题报告——自行车配件管理系统...¥0 课程设计 CA6140车床拨叉831002的加工工艺及钻φ25孔的钻床...¥0

课程设计 CA6140车床拨叉831002的加工工艺及钻φ25孔的钻床...¥0 补价¥1.00

补价¥1.00 毕业设计辅助工具_免费在线论文文案文章修改神器_毕业设计辅助软件_AI...¥0

毕业设计辅助工具_免费在线论文文案文章修改神器_毕业设计辅助软件_AI...¥0 六自由度工业机器人设计【说明书(论文)+CAD图纸+SolidWork...¥45.00

六自由度工业机器人设计【说明书(论文)+CAD图纸+SolidWork...¥45.00 陈家沟桥梁施工组织设计方案.doc...¥0

陈家沟桥梁施工组织设计方案.doc...¥0振动压路机是利用其自身的重力和振动压实各种建筑和筑路材料。在公路建设中,振动压路机最适宜压实各种非粘性土壤、碎石、碎石混合料以及各种沥青混凝土而被广泛应用。目前国产振动压路机以中小吨位和机械传动方式为主,而性能优良的全液压重型振动压路机主要依赖于进口。之所以出现处于这种状况是由于全液压压路机液压传动系统结构比较复杂并且各类液压元件加工复杂,为彻底改变这种现状本文对现有压路机液压系统进行调研,研制出结构优良的全液压压路机传动系统。

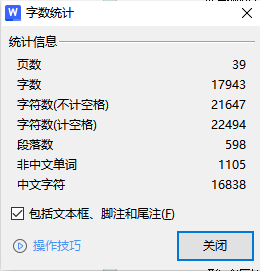

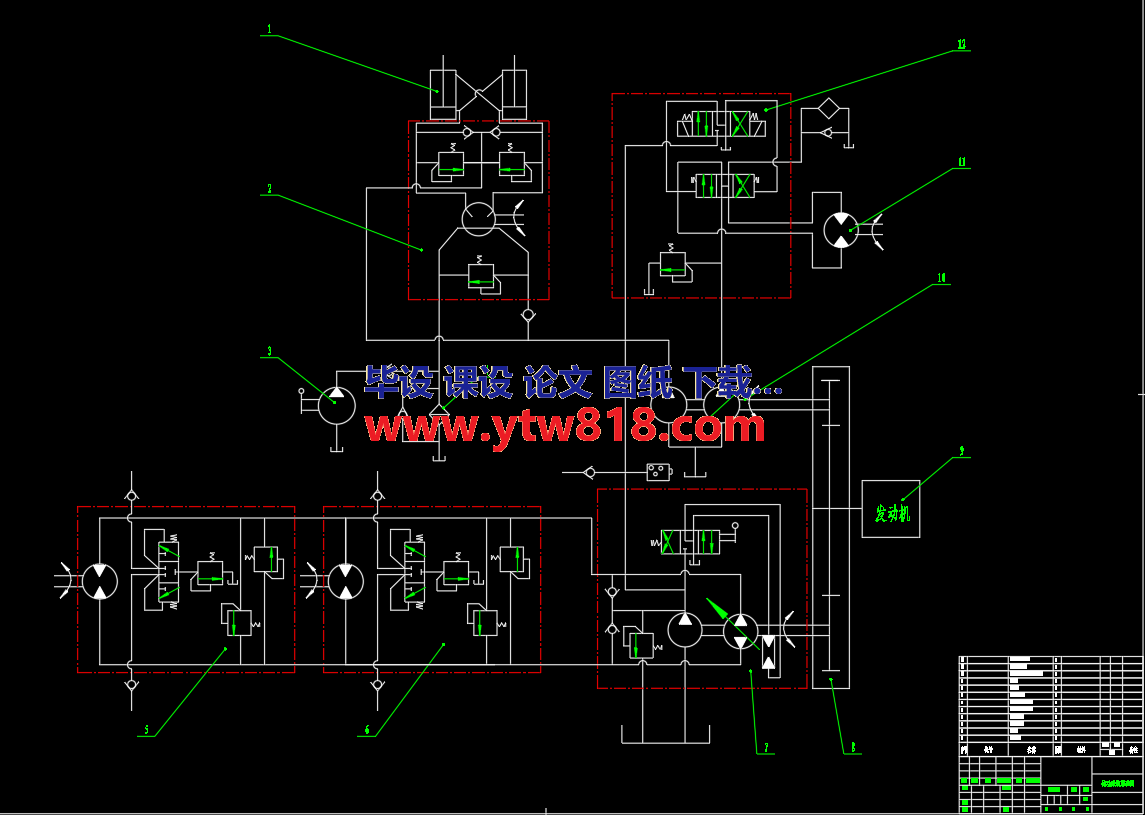

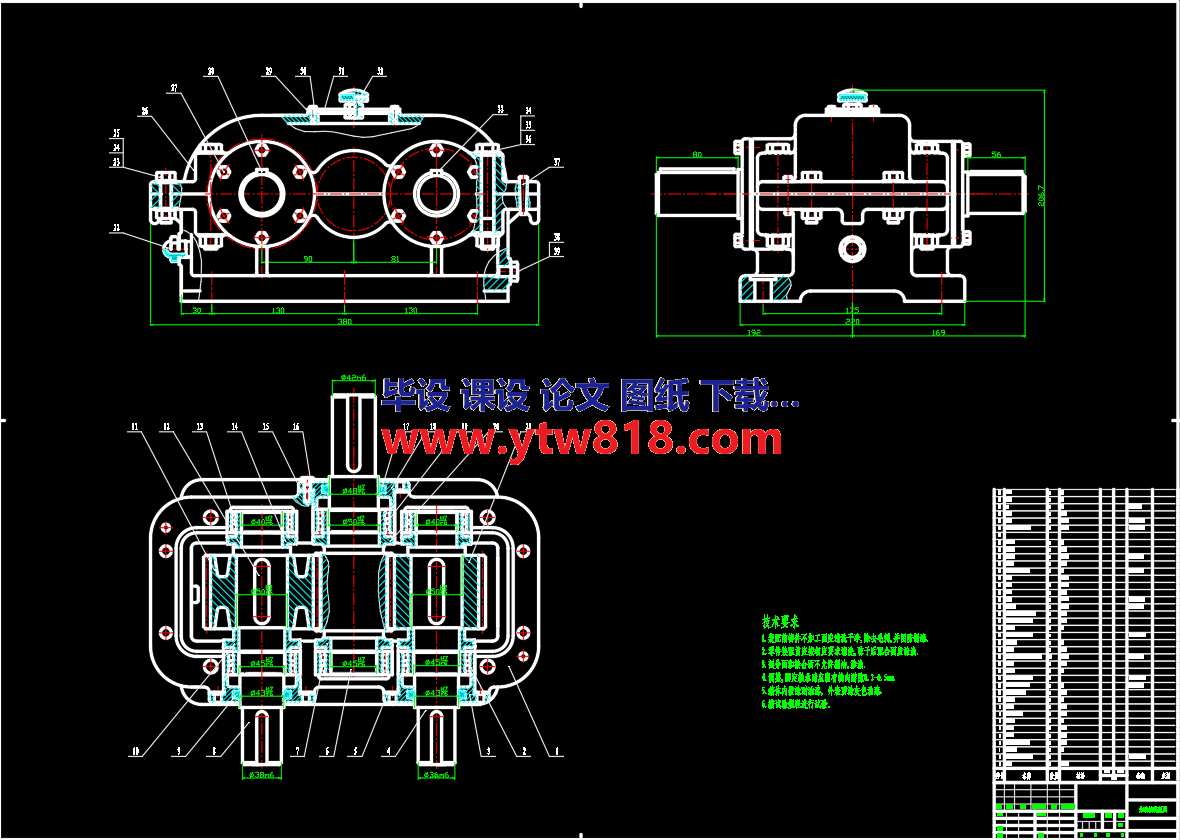

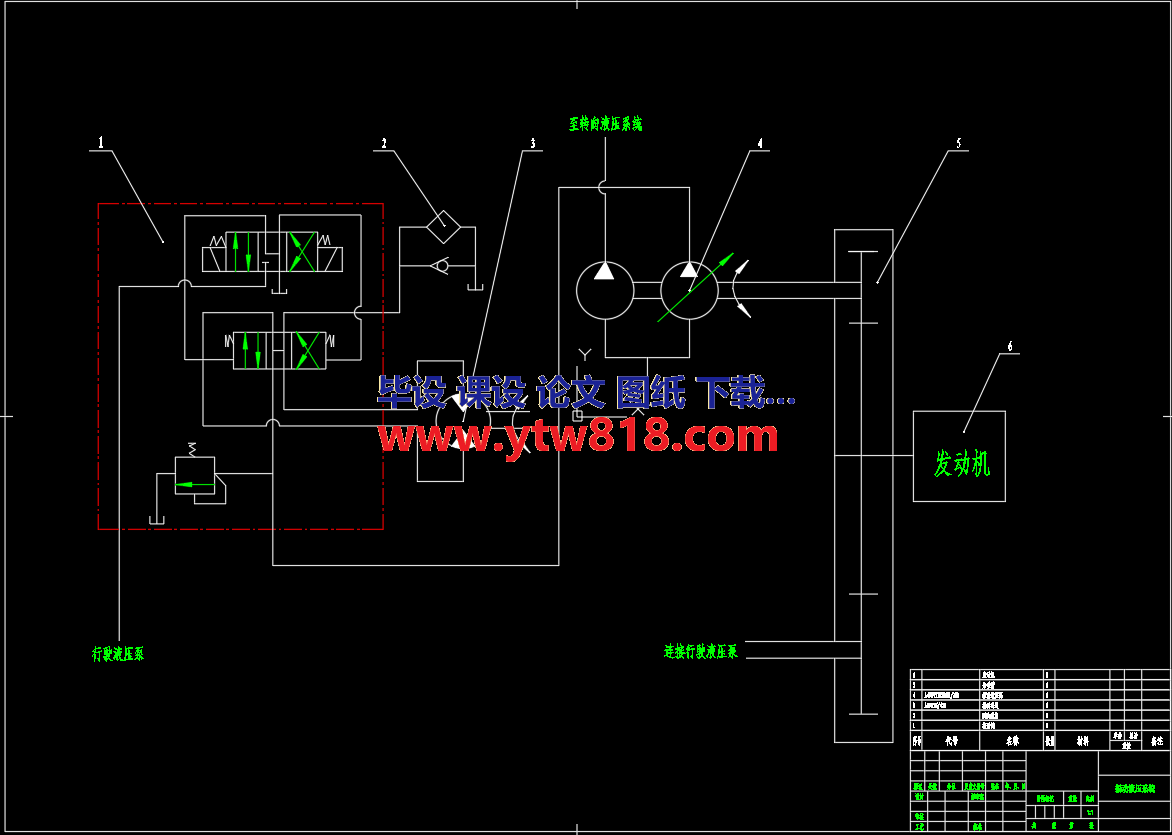

本文在理论分析和计算的基础上,完成了YZ16型振动压路机液压系统的设计,在方案、结构和设计方法上进行了创新:采用全液压的传动方案,通过3个相互独立的液压回路实现行驶、振动和转向三大基本功能,与机械传动相比在压实效果、爬坡能力、质量分配、操作控制和整体布局方面具备更大优势。转向结构采用铰接式车架折腰转向的方案,转弯半径小、机动性好、前后轮迹重叠、重心低、驾驶员视野开阔。同时本文对分动箱的机构进行了详细的设计计算,为缩小分动箱的体积本次采用齿面硬度达60HRC的齿轮和双列滚柱轴承的结构。

关键词:振动压路机;设计;液压系统;分动箱

Vibratory roller is to use its own gravity and vibration compaction variety of building and road construction materials . In highway construction, the most suitable vibratory roller compacted variety of non- cohesive soils , gravel, crushed stone and a variety of asphalt concrete mixture has been widely used . Current domestic vibratory roller to small and medium tonnage and mechanical transmission mode based, and excellent performance heavy-duty hydraulic vibratory roller mainly dependent on imports. The reason why this situation is due in full hydraulic roller hydraulic system structure is more complex and complicated processing all types of hydraulic components , to completely change the situation this roller hydraulic system on the existing research , developed a well-structured full hydraulic roller transmission .

Based on the theoretical analysis and calculation , based on the completed YZ16 type vibratory roller hydraulic system design, program , structure and design methods on the innovation : the use of full hydraulic transmission scheme by three independent hydraulic circuits to achieve with , vibration and steering three basic functions , compared with mechanical transmission in the compaction effect , climbing ability , quality and distribution , operation control and overall layout has a greater advantage. Articulated frame steering structure using bow steering programs , small turning radius , mobility, front and rear tracks overlap , low center of gravity , driver vision . Meanwhile this paper Transfer case institutions carried out a detailed design calculations, in order to narrow the volume Transfer case The tooth surface hardness of 60HRC using gears and double row roller bearing structure .

Keywords: Vibrating roller ; Design ; Hydraulic system ; Transfer case

目录

压路机在工程机械中属于道路设备的范畴,广泛用于高等级公路、铁路、机场跑道、大坝、体育场等大型工程项目的填方压实作业,可以碾压沙性、半粘性及粘性土壤、路基稳定土及沥青混凝土路面层。全液压振动压路机是利用其自身的重力和振动压实各种建筑和筑路材料。在公路建设中,振动压路机最适宜压实各种非粘性土壤、碎石、碎石混合料以及各种沥青混凝土而被广泛应用。

根据压实机械的工作原理、结构特点、传动形式、操作方法和用途的不同,有不同的分类方法,习惯上把压实机械分为压路机和夯实机两大类: 1、压路机:按压实原理,压路机可分为静作用压路机、振动压路机和组合式压路机。静作用压路机又可分为光轮压路机和轮胎压路机。振动压路机可分为手扶式振动压路机、自行式振动压路机、两钢轮串联式振动压路机和拖式振动压路机。振动压路机按振动机构分又可分为:圆周振动;扭转振动即振荡;智能振动,其中包括:垂直振动、斜向振动和水平振动;复式振动即扭转振动和轴向振动的叠加:混沌振动压路机即主频附近的宽频激振。2、夯实机:夯实机有蛙式打夯机、振动平板夯、振动冲击夯和爆炸夯四种。振动平板夯又可分前行和可逆行振动平板夯两种。振动冲击夯又分为电动和内燃振动冲击夯两种。

…………

…………