毕业设计辅助工具_免费论文文案文章修改神器_毕业设计辅助软件_论文查重...¥0

毕业设计辅助工具_免费论文文案文章修改神器_毕业设计辅助软件_论文查重...¥0 solidworks2018 中文版¥0

solidworks2018 中文版¥0 CA6140车床拨叉831006零件夹具设计说明书——9页...¥0

CA6140车床拨叉831006零件夹具设计说明书——9页...¥0 机械设计制造及其自动化毕业设计(论文)开题报告...¥0

机械设计制造及其自动化毕业设计(论文)开题报告...¥0 XX大学理工类毕业设计(论文)开题报告——自行车配件管理系统...¥0

XX大学理工类毕业设计(论文)开题报告——自行车配件管理系统...¥0 课程设计 CA6140车床拨叉831002的加工工艺及钻φ25孔的钻床...¥0

课程设计 CA6140车床拨叉831002的加工工艺及钻φ25孔的钻床...¥0 补价¥1.00

补价¥1.00 毕业设计辅助工具_免费在线论文文案文章修改神器_毕业设计辅助软件_AI...¥0

毕业设计辅助工具_免费在线论文文案文章修改神器_毕业设计辅助软件_AI...¥0 六自由度工业机器人设计【说明书(论文)+CAD图纸+SolidWork...¥45.00

六自由度工业机器人设计【说明书(论文)+CAD图纸+SolidWork...¥45.00 陈家沟桥梁施工组织设计方案.doc...¥0

陈家沟桥梁施工组织设计方案.doc...¥0摘要

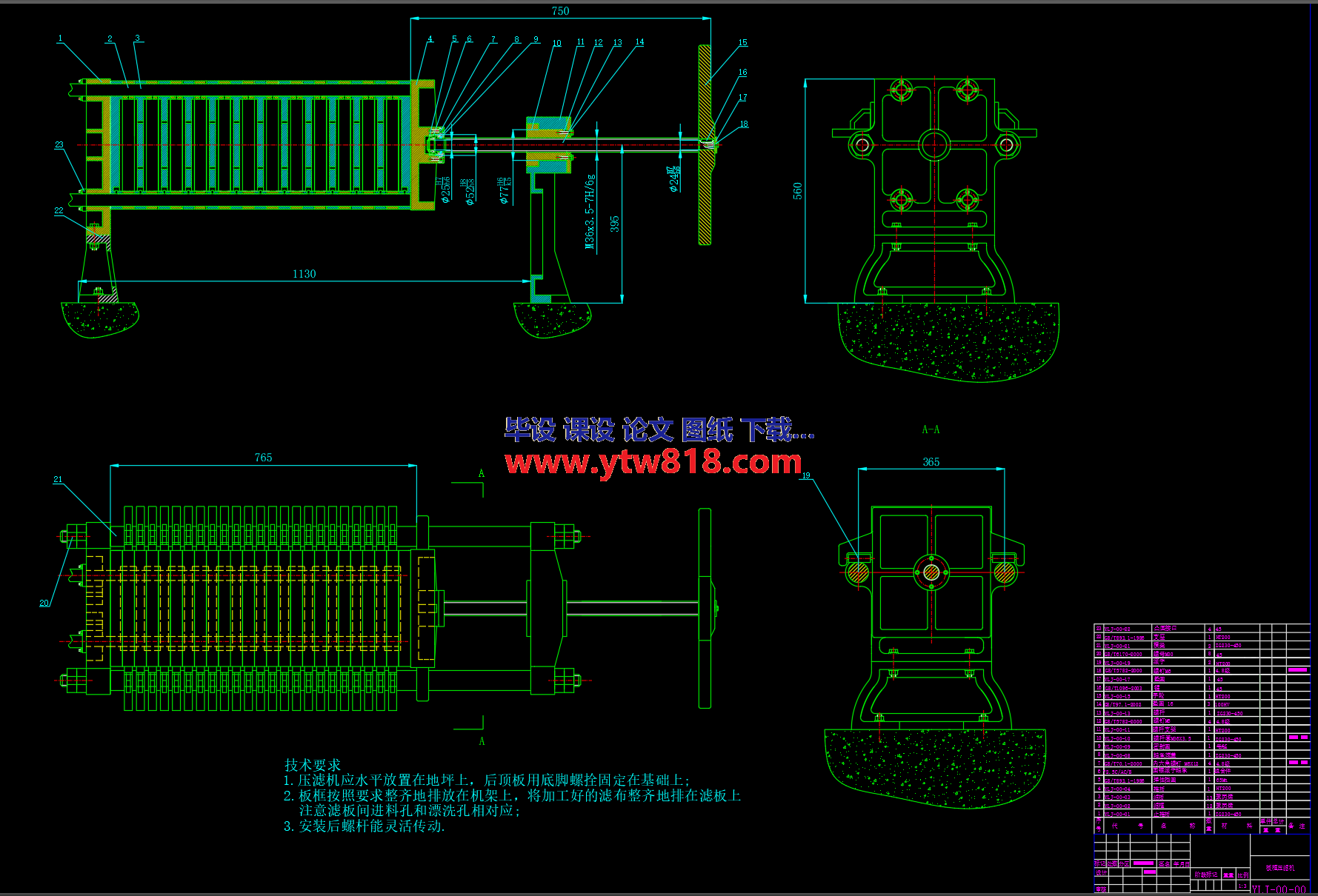

压滤机是利用多孔性过滤介质,拦截混合固体颗粒的液体和固体颗粒,实现固体和液体分离的设备。压滤机广泛应用于化工、石油、制药、轻工、食品、选矿、煤炭和水处理等。目前,现有数百个大型压滤机制造商。为了满足产业发展的需求,市场上已经出现了各种不同的类型压滤机。根据获得过滤的推动力不同,分为重力过滤,真空过滤机和三种类型的压滤机。板框压滤机压紧方式有手动压缩、机械压缩和液压三种形式。正在开发一种新型的过滤设备有:机械力压过滤设备;实现无动态过滤滤饼层;洗煤废水处理、化工和石油等行业大型过滤设备。设计的手工板框过滤机。它的优点是结构简单,容易制造,过滤面积大,占地面积小,操作压力高、能力强的各种材料的应用,主要用于小企业,小批量生产。

关键词:过滤机 过滤面积 滤板 滤框

Abstract

Filter is the use of porous filter medium, retain the mixture of liquid and solid particles, solid particles, and to achieve solid, liquid separation equipment. Filter is widely used in chemical, petroleum, pharmaceutical, light industry, food, mineral processing, coal and water treatment sectors. Currently, hundreds of our existing large filter manufacturers. To meet the requirements of the industry and the market has been the emergence of various different models and methods of filter .Be driven by different methods of filtration, divided into gravity filters, vacuum filters and pressure filter categories. Pressed mode frame filter press with manual compression, mechanical compression and hydraulic clamping three forms. Is developing a new type of filtration equipment: mechanical press filtration equipment; to achieve residue-free layer of filtering a dynamic filter; Coal washing waste water treatment, chemical and oil industry equipment used in large filtration. The design of the filter frame for the hand over machine. It has the advantage of simple structure, easy to filter area and small size, operating pressure is high, the application of the ability of various materials, mainly small-batch production and small business applications

Key Words:Filter Filter area Plates Filter box

目录

1.2 板框压滤机的简介及分类 2

3. 板框压滤机的操作规程 18

4. 板框压滤机的保养维护 19

绪论

20世纪初,转鼓真空过滤机实现了操作上的连续过滤。自那时以来,各种类型的压滤机出现。间歇运行的压滤机因能实现自动化操作而得到发展,随着生产能力的进一步发展,过滤面积越来越大。压滤机应该基于泥浆的浓度,固体颗粒大小,液体粘度和选择压滤机的质量要求。使用过滤漏斗实验,测定不同过滤介质和过滤速度不同压差下,滤液固体颗粒含量,滤饼层的厚度和含水量,找出适当的过滤条件,初步选定的压滤机类型。然后根据定处理量选定过滤面积的容量,和实际测试。正在开发一种新型的过滤设备有:机械力压滤过滤设备;实现无动态过滤滤饼层;洗煤废水处理、化工和石油等行业大型使用过滤设备。在过滤理论研究,残留在滤室内的滤饼其过滤阻力的计算和孔隙度、过滤速度、过滤设备模拟和放大,液体澄清过滤和动态过滤机制,以及过滤介质,是重要的课题。

………………