玉米脱粒机的设计(说明书+cad图纸+pro三维图+SW三维图+开题报...¥45.00

玉米脱粒机的设计(说明书+cad图纸+pro三维图+SW三维图+开题报...¥45.00 手机壳模具(UG8.5)¥0

手机壳模具(UG8.5)¥0 CAD字体¥0

CAD字体¥0 花生剥壳去壳机(cad+pro+SolidWorks+三维通用格式st...¥49.00

花生剥壳去壳机(cad+pro+SolidWorks+三维通用格式st...¥49.00 6个自由度的水果采摘机械手结构设计【CAD图+SW三维模型+文献翻译+...¥49.00

6个自由度的水果采摘机械手结构设计【CAD图+SW三维模型+文献翻译+...¥49.00 PLC控制的一种平面关节型机器人设计 PDF...¥0

PLC控制的一种平面关节型机器人设计 PDF...¥0 灾害救援机器人的设计(说明书+CAD图纸+SOLIDWORKS三维图+...¥50.00

灾害救援机器人的设计(说明书+CAD图纸+SOLIDWORKS三维图+...¥50.00 自动化立体仓库堆垛机设计(设计说明书+17张CAD图纸+开题报告+任务...¥49.00

自动化立体仓库堆垛机设计(设计说明书+17张CAD图纸+开题报告+任务...¥49.00 毕业设计 螺旋输送机设计(论文+CAD图纸+SolidWorks三维图...¥49.00

毕业设计 螺旋输送机设计(论文+CAD图纸+SolidWorks三维图...¥49.00 绞肉机的设计【16张CAD图纸+毕业论文】...¥43.00

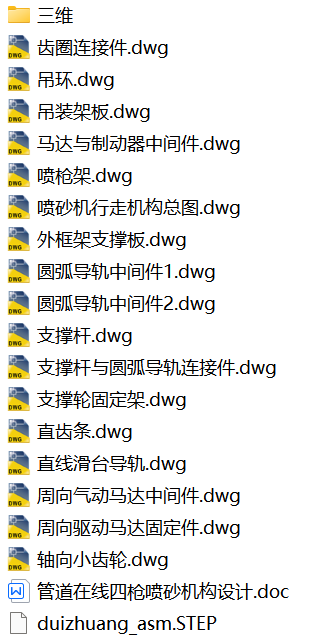

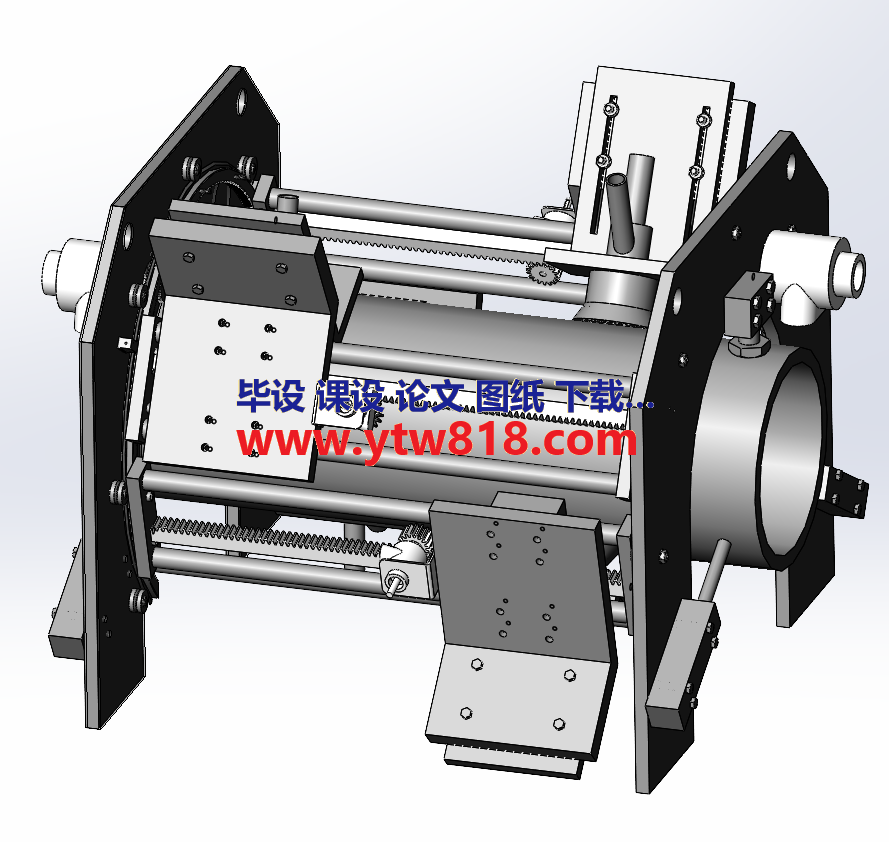

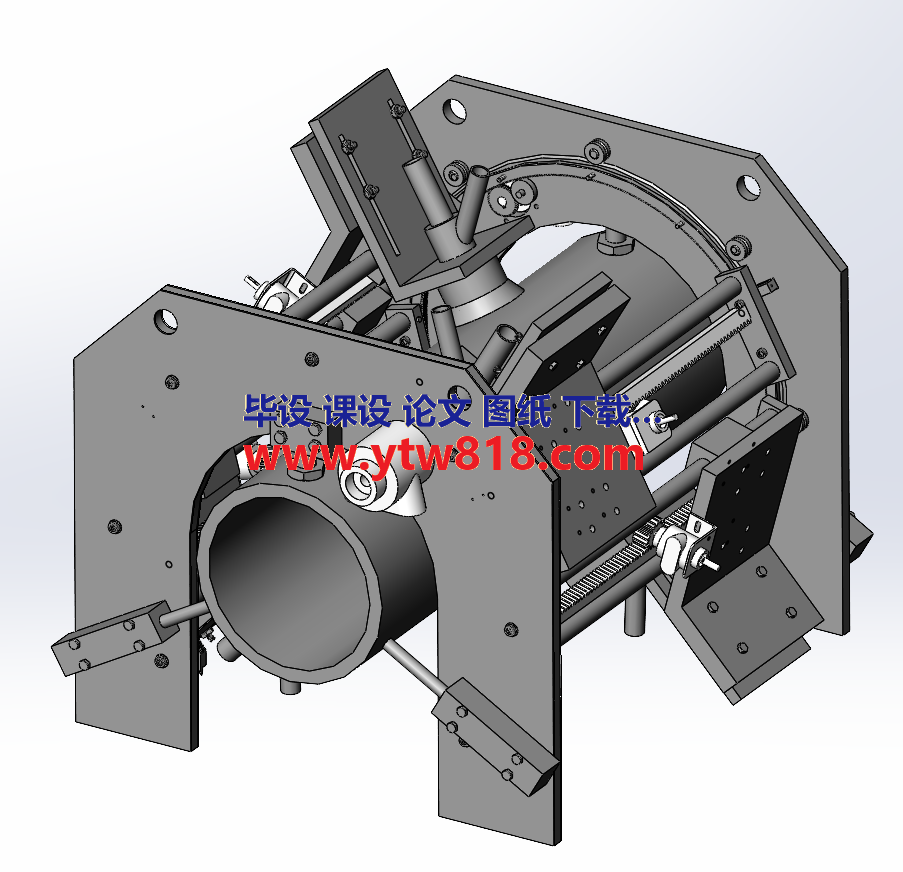

绞肉机的设计【16张CAD图纸+毕业论文】...¥43.00目前的管道喷砂工艺,大多采用的还是人工露天作业,存在工作环境差、劳动强度大、损坏设备快、污染严重、处理质量不稳定等严重问题,此次设计主要就是针对这些方面,特别针对大型管道喷砂的工作台及其行走机构进行设计,主要设计内容如下:

一是改变以往立式双夹板支撑地面的树立结构为吊式利用铁柱与铁荚来固定喷砂机自行走部分:二是为了减少自身负重造成的笨重难以移动和制造喷砂机所需的刚材料过多等问题,利用新的结构大幅度减少了不必要支撑部位,承重没有问题:三是把以往封闭的环式结构,只能通过像套筒一样从一头到另一头这种既占空间又有高出错成本的方案改进成可开闭的结构,这样可以从任意地方开始加工管道,简单方便,因此为工人加工提供便利,通过管道的移动进行加工,工人可以站在原地,不必长距离奔走。四是变二喷砂枪为四喷砂枪,这可以大大提高工作效率,大约在2倍以上。

该在线管道喷砂机构使得喷砂做到快速、平稳,提高了自动化程度,操作方便,运行可靠,实现了钢管外表面的自动喷砂处理,提高了产品质量,改善了工作环境。

The pipeline blasting process at present, most of the artificial still existing open-air operations, poor working environment, high labor intensity, equipment damage and serious pollution, fast processing quality is not stable and other serious problems, this design is mainly based on these aspects, especially for the large table and walking mechanism of blasting pipeline design, the main design contents are as follows:

One is to change the structure of the past to establish vertical double splint for supporting the ground hanging by iron and iron pod fixed sandblasting machine self-propelled parts: two in order to reduce their weight problems caused by heavy and difficult to move manufacturing sandblasting machine required just too much material, the use of the new structure greatly reduces unnecessary support part three: no problem, bearing the previous closed ring type structure, only through the sleeve like from one end to the other end of this occupies space and has high error cost improvement scheme structure which can be opened and closed, it can be from any place to start processing pipeline, simple and convenient, thus providing convenience for workers processing, which is processed by the pipeline mobile workers can stand in situ, without long distance running. Four is to change the two sand blasting gun for the sand blasting gun, which can greatly improve the efficiency of about 2 times more than four.

The online pipeline blasting mechanism makes the blasting to achieve rapid, stable, and improve the degree of automation, convenient operation, reliable operation, automatic sandblasting pipe external surface, improve product quality, improve the working environment.

Key Words: Sandblasting;Machine Efficiency;Improvement in the Structure of Open Type

摘要 1

ABSTRACT 2

目 录 3

第一章 绪论 4

1.1 研究的目的和意义 4

1.2 喷砂技术的发展与应用 4

第二章 管道喷砂机构研究 8

2.1 喷砂技术概述 8

2.2 总体方案选择 11

第三章 机构的选择 18

第四章 计算 20

4.1 电动机的选择 20

4.2 确定电动机转速 20

4.3传动装置的总传动比和分配各级传动比 21

4.4 传动装置的运动和动力参数的计算 21

4.4.1计算各轴的转速 21

4.4.2 计算各轴的输入功率和输出功率 21

4.4.3 计算各轴的输入转矩和输出转矩 21

4.4.4 初定各轴最小直径 22

第五章 齿轮传动的设计计算 23

5.1 初步计算的许用接触应力 23

5.2校核计算 24

5.3 确定传动主要尺寸 26

总结 29

参考文献 30

致 谢 32

………………