玉米脱粒机的设计(说明书+cad图纸+pro三维图+SW三维图+开题报...¥45.00

玉米脱粒机的设计(说明书+cad图纸+pro三维图+SW三维图+开题报...¥45.00 手机壳模具(UG8.5)¥0

手机壳模具(UG8.5)¥0 CAD字体¥0

CAD字体¥0 花生剥壳去壳机(cad+pro+SolidWorks+三维通用格式st...¥49.00

花生剥壳去壳机(cad+pro+SolidWorks+三维通用格式st...¥49.00 6个自由度的水果采摘机械手结构设计【CAD图+SW三维模型+文献翻译+...¥49.00

6个自由度的水果采摘机械手结构设计【CAD图+SW三维模型+文献翻译+...¥49.00 PLC控制的一种平面关节型机器人设计 PDF...¥0

PLC控制的一种平面关节型机器人设计 PDF...¥0 灾害救援机器人的设计(说明书+CAD图纸+SOLIDWORKS三维图+...¥50.00

灾害救援机器人的设计(说明书+CAD图纸+SOLIDWORKS三维图+...¥50.00 自动化立体仓库堆垛机设计(设计说明书+17张CAD图纸+开题报告+任务...¥49.00

自动化立体仓库堆垛机设计(设计说明书+17张CAD图纸+开题报告+任务...¥49.00 毕业设计 螺旋输送机设计(论文+CAD图纸+SolidWorks三维图...¥49.00

毕业设计 螺旋输送机设计(论文+CAD图纸+SolidWorks三维图...¥49.00 绞肉机的设计【16张CAD图纸+毕业论文】...¥43.00

绞肉机的设计【16张CAD图纸+毕业论文】...¥43.00摘要

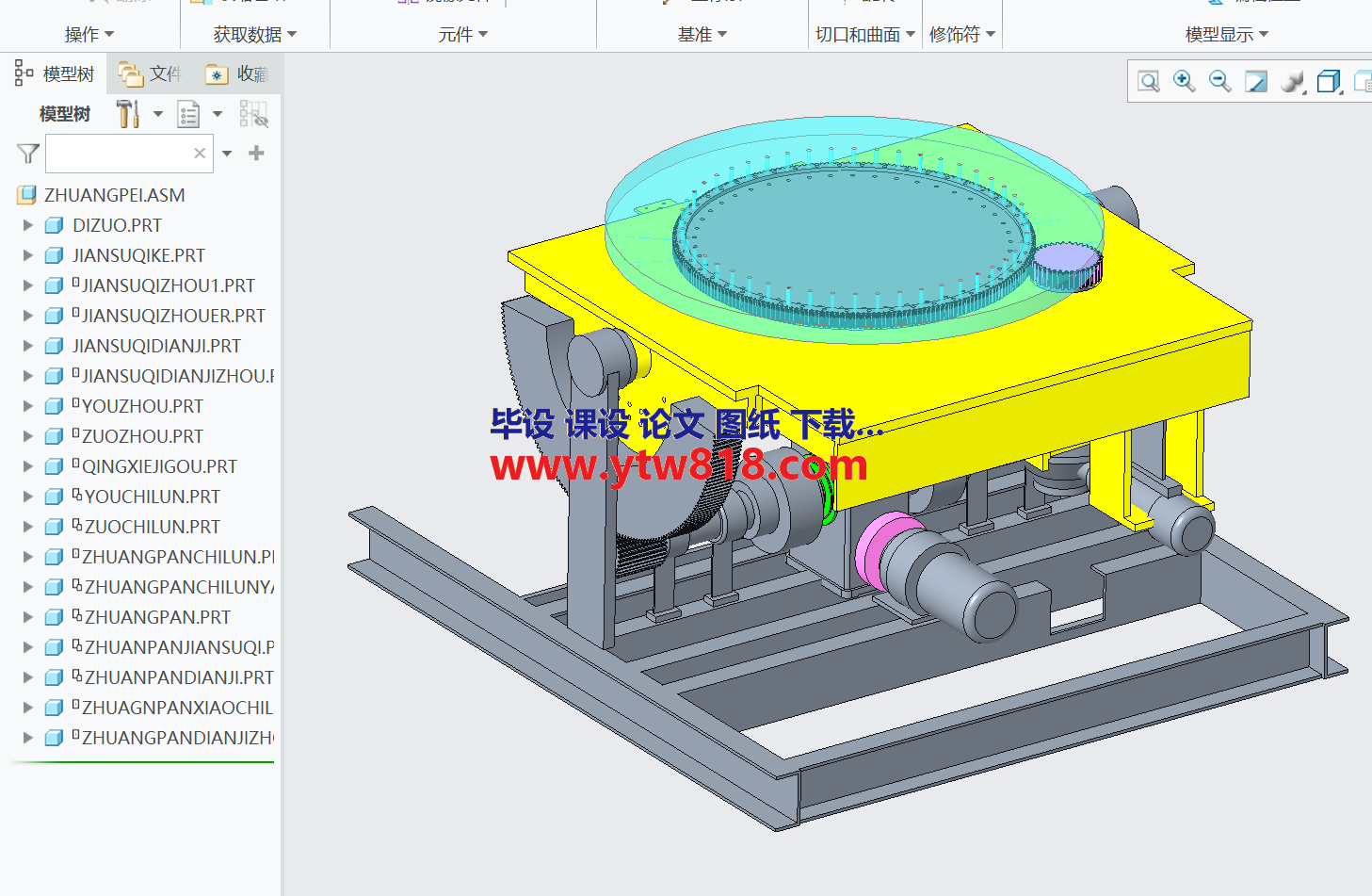

焊接变位机的目的是使焊接可以变得机械化和自动化,原理是通过改变焊接工件的位置使每一处的焊接都方便操作,达到减少时间、空间、人工成本的目的,从而达到更高的生产率,不仅可以降低工人的工作量,还能获得较高焊接质量,并且能够充分发挥各种焊接方法的效能。焊接变位机现在已经成为制造业中必不可少的设备之一,在焊接领域把它划分为焊接辅助机,其分类约有十余个系列、百余个品种,正在形成一个新兴行业。

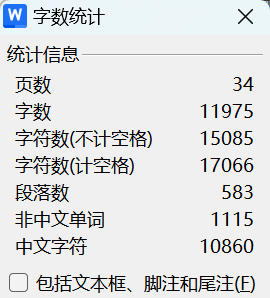

本论文设计的是能够承受60吨工件,可两个方向旋转的变位机。涉及到的内容主要为:1、焊接工作台的设计(包括回转系统、翻转系统);2、减速器的设计及零件的选择;3、传动齿轮的设计;4、各种轴承的验证计算。

主要是通过焊接变位器所承受的重量、体积和焊接所需的速度等参数来确定焊接变位机需要的合适电动机类型(主要是转速、额定功率、使用寿命),从而在此基础上计算齿轮传动相关数据、旋转或翻转支承的型号和其他所需零件的型号,然后对已选择的零件进行强度、使用寿命等参数的计算比较,从而确定齿轮、轴承类型,最后使用软件绘制所用的零件图、总图。

关键词 焊接;变位机;传动机构;减速机;齿轮

Abstract

Welding positioner is to change the welding part of the space position to achieve mechanical, automatic welding of mechanical equipment. By welding variable bit machine can effectively shorten the auxiliary time of welding, so as to achieve higher productivity, not only can reduce workers' workload, but also get high welding quality, and can give full play to the performance of various welding methods. Welding positioner has now become one of the essential industry equipment manufacturing, dividing it to computer aided welding in the welding area, and the classification about more than 10 series, over a hundred varieties, is in the form of an emerging industry.

This paper is designed to withstand 60 tons of workpiece, can be rotated in two directions. The main content is about the welding time table rotating mechanism and the control of the turnover mechanism, the choice of motor, reducer design or selection, the design of the transmission gear, each axis and bearing, as well as check and so on.

The specific process of the design is to determine the type of motor required for the equipment according to the predetermined load and the requirements of the welding speed, including: motor speed, rated power, weight, volume, etc.On the basis of the calculation of the gear transmission related data, the model of the rotary support andand other parts of the model, and strength of the selected parts, use life parameters calculation comparison and thus the determination of gear and bearing type, finally uses the software drawing of the parts of the map, the map.

Keywords Welding Position changing machine Drive mechanism Speed Reductor Gear Wheel

目录

摘要I

AbstractII

1 绪论1

1.1研究创新焊接变位机的意义和目的1

1.2焊接变位机的国内外的概况1

1.2.1 焊接变位机的国内的发展概况1

1.2.2 焊接变位机的国外的发展概况2

1.3 本课题的研究方法和要解决的问题2

2 总体设计3

2.1设计依据3

2.2 设计的基本参数3

2.3 变位机的总体方案设计3

2.4 驱动系统方案4

2.4.1 工作台回转方案4

2.4.2 工作台翻转方案4

3 回转机构设计5

3.1 工作台回转机构5

3.2 选择回转工作台的电机5

3.3 减速器的选择6

3.4 回转支承的选择7

3.4.1回转系统承载的总重量7

3.4.2计算回转支承的最大倾覆力矩8

3.4.3小齿轮1的参数(即与回转支承啮合的小齿轮)9

4 翻转机构设计12

4.1 工作台翻转机构12

4.2 选择翻转机构的电机12

4.3 蜗杆减速器13

4.3.1 蜗杆和蜗轮的设计13

4.3.2 蜗杆轴和蜗轮轴的设计16

4.4扇形齿轮传动设计16

4.5 翻转机构中轴的设计18

4.5.1 翻转轴的最小直径18

4.5.2 校核箱形梁的强度19

4.6 联轴器的选用计算19

4.6.1 减速器与减速器之间的联轴器19

4.6.2 减速器与齿轮轴之间的联轴器20

4.7 轴承的选用和校核20

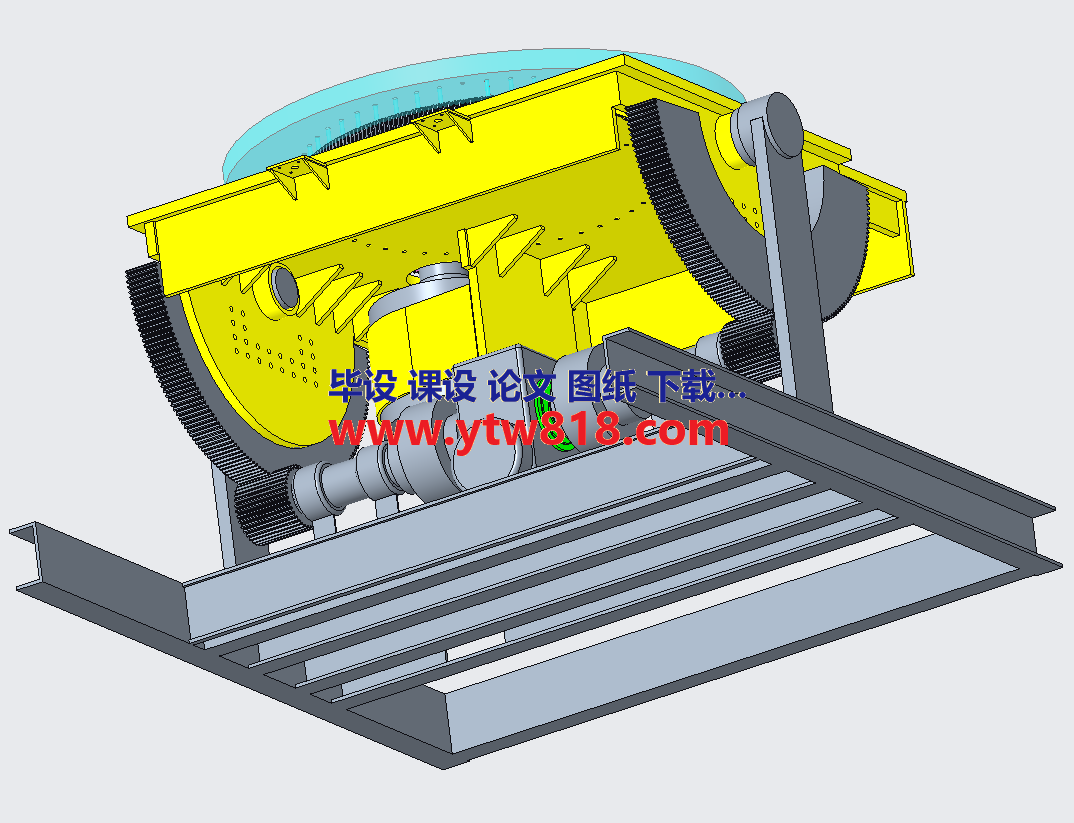

5 电气控制部分22

6 三维建模和仿真23

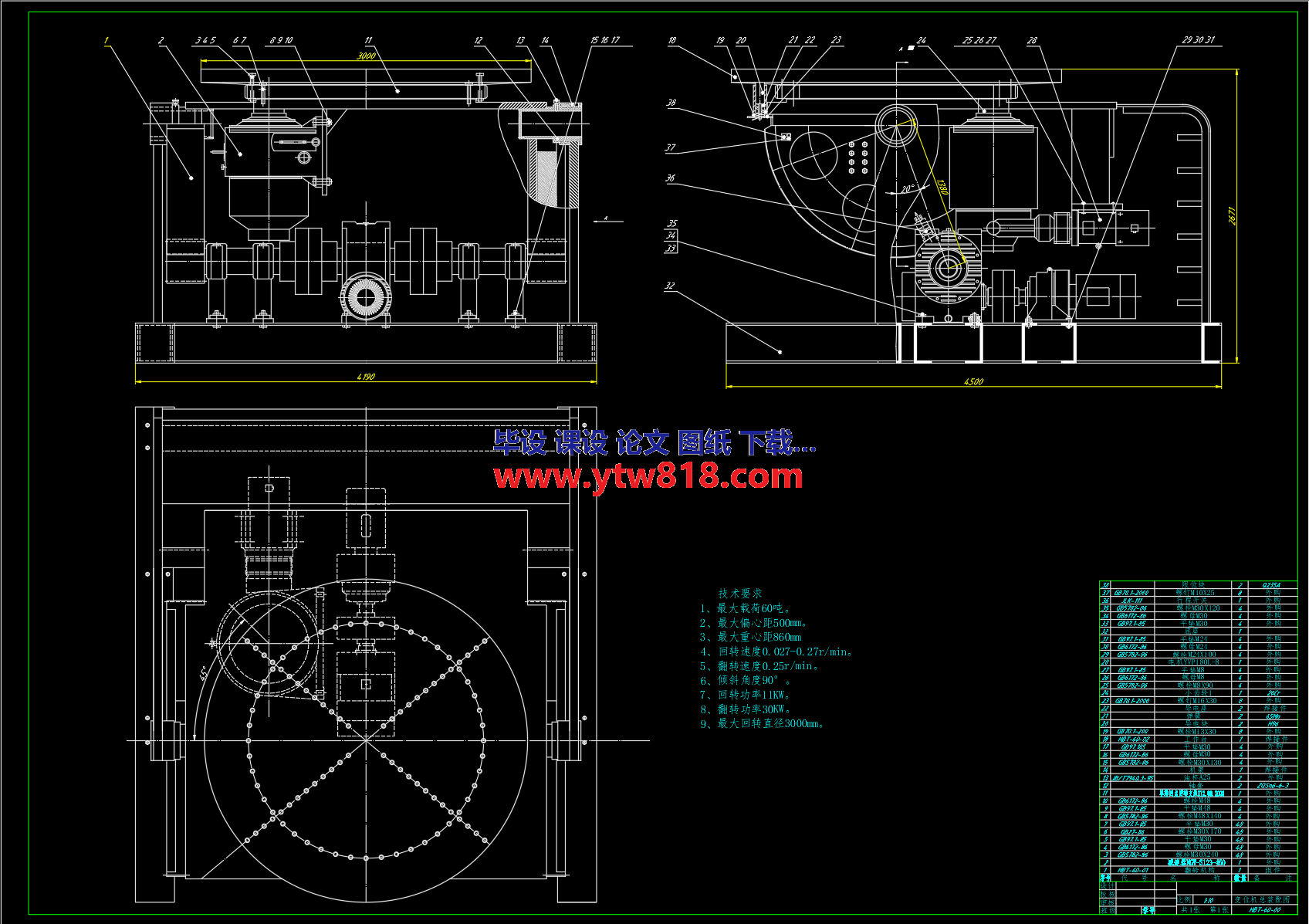

6.1 零件建模23

6.2 整机装配24

6.3 伺服机构的设置26

6.4 机构仿真26

结论28

致谢29

参考文献30

………………