毕业设计辅助工具_免费论文文案文章修改神器_毕业设计辅助软件_论文查重...¥0

毕业设计辅助工具_免费论文文案文章修改神器_毕业设计辅助软件_论文查重...¥0 solidworks2018 中文版¥0

solidworks2018 中文版¥0 CA6140车床拨叉831006零件夹具设计说明书——9页...¥0

CA6140车床拨叉831006零件夹具设计说明书——9页...¥0 机械设计制造及其自动化毕业设计(论文)开题报告...¥0

机械设计制造及其自动化毕业设计(论文)开题报告...¥0 XX大学理工类毕业设计(论文)开题报告——自行车配件管理系统...¥0

XX大学理工类毕业设计(论文)开题报告——自行车配件管理系统...¥0 课程设计 CA6140车床拨叉831002的加工工艺及钻φ25孔的钻床...¥0

课程设计 CA6140车床拨叉831002的加工工艺及钻φ25孔的钻床...¥0 补价¥1.00

补价¥1.00 毕业设计辅助工具_免费在线论文文案文章修改神器_毕业设计辅助软件_AI...¥0

毕业设计辅助工具_免费在线论文文案文章修改神器_毕业设计辅助软件_AI...¥0 六自由度工业机器人设计【说明书(论文)+CAD图纸+SolidWork...¥45.00

六自由度工业机器人设计【说明书(论文)+CAD图纸+SolidWork...¥45.00 陈家沟桥梁施工组织设计方案.doc...¥0

陈家沟桥梁施工组织设计方案.doc...¥0目前机械转动应用的带式无级变速器主要是带传动无级变速器。广泛应用于机械、石油汽车等行业。机械、石油行业多采用橡胶宽V带式,自动档汽车采用金属带式无级变速器。无级调速原理目前主要采用国外技术专利引进的挤压带传动式带传动无级变速技术,调速挤压力产生的主要问题:①橡胶V带磨损、热变形严重,寿命短,承载能力降低;②金属带成本高;③调速时主、从动轮传动带不在同一工作平面内;④传动带承载能力计算超出柔性体传动的欧拉公式范围;⑤带轮槽为曲线形状,加工成本高,尤其无法在家用电动轿车普遍应用等。

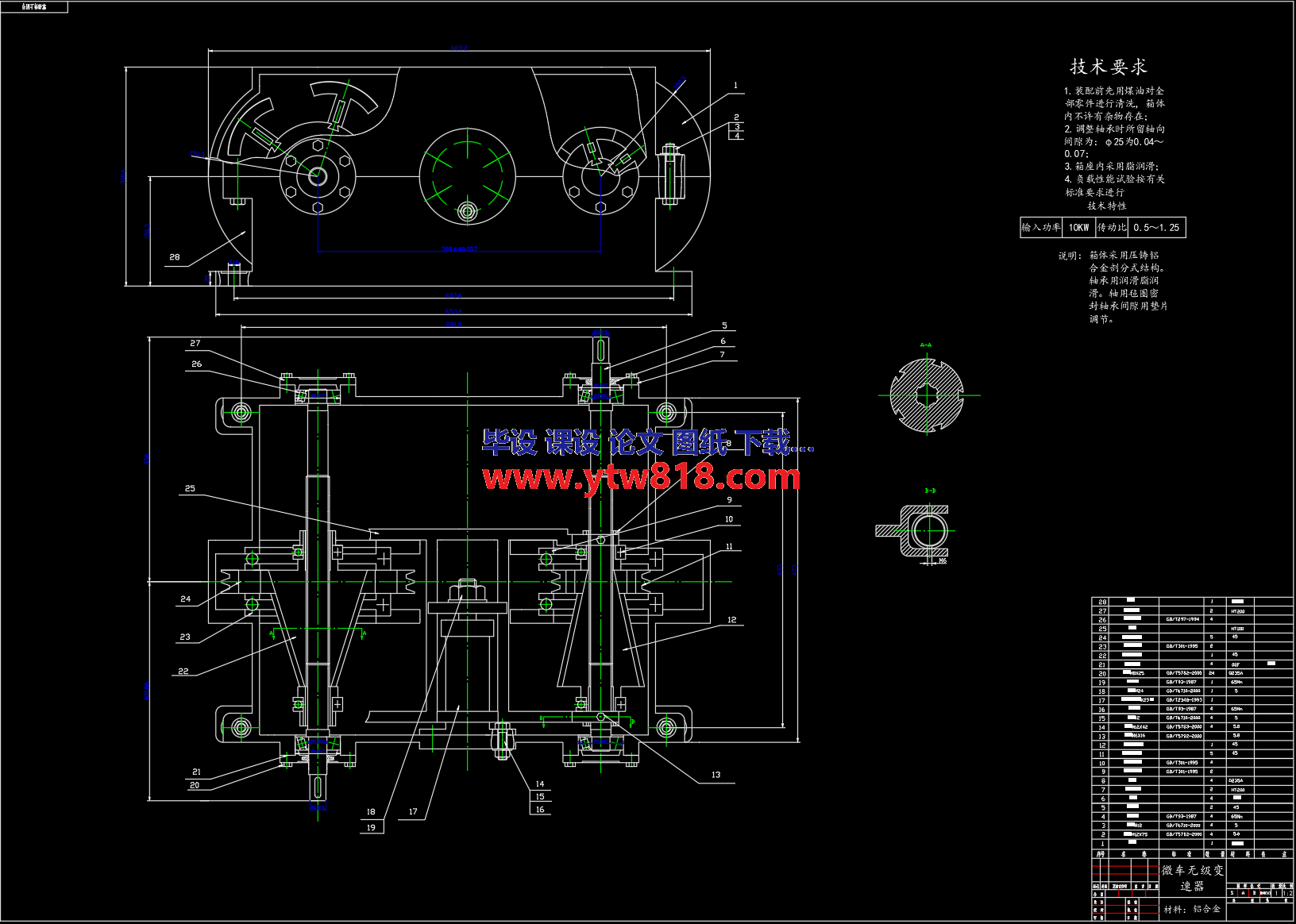

通过调研分析,采用分体带轮结构设计,开发新型带传动无级变速器,使其能满足家用微型轿车使用要求,调速时带轮分体在调速机构的作用下可以沿径向连续膨胀或收缩,达到改变带轮的工作直径,实现无级变速目的,消除了作用在V带侧面的挤压力带轮的问题。

毕业课题论文研究主要完成了以下工作:

1、 对分体带轮带传动无级变速器的工作原理以及各部分的主要功能分析,说明了新型V带无级变速器可以满足传动要求;

2、 结合设计参数的要求,完成了分体带轮带传动无级变速器主要零件(锥体轴和带轮分体等)的结构尺寸设计;

研究工作取得以下成果:

1、 创新提出分体带轮结构,通过调速控制机构可以改变主从动带轮的工作直径,实现连续无级变速;

2、 结构简单,成本低,适用性强〔可适应普通V带、平带、圆带、楔型带无级变速);

3、 调速时消除了作用在传动带侧面的挤压力,减小由此产生的传动带的过大磨损等问题;

4、 总结出分体式V带传动无级变速器的有效圆周力计算方法。

关键词:带式传动;无级变速器;分体带轮

The belt-type continuously variable transmission (CVT) has been widely used in the mechanics and the fields of petroleum and automobiles nowadays. To be exact, the rubber V-belt CVT is adopted for the mechanics and petroleum, while the metal CVT is used for automatic automobile. The working principle of CVT is mainly based on the technology of the pressed belt type CVT, which is of abroad technology patent. The main problem involves (1) the likely wear of rubber V belt the serious deformation from heat, the short service life and the reduced capacity of carrying.(2 )the high cost of metal belt.(3 )The main belts and auxiliary belts are not in the same working horizon when regulating speed. (4) The calculation on carrying capacity is beyond the format. (5) The pulley sleeve is in the form of curve, and the cost of production is too high.

By careful analysis,The use of the structural design of split pulley,development of new CVT Belt Drive,To enable them to meet the requirements of domestic use of electric cars。It proves to reduce the wear of belt and avoid misalignment of pulleys to a large extent by adopting the parted pulleys and unique mood to vary speed.

The study work has been completed as follows:

1. It proves that this new type of CVT can meet the driving requirement by analyzing the working principle of CVT with parted pulleys and main functions of each component.

2. The dimension of main components of CVT with parted pulleys has been designed in fully compliance with the requirement of design parameters.

3. The design plan has been optimized and the best parameters of construction of CVT with parte pulleys has been determined by the stress analysis, with the result that the parted block can change the working diameter by means of moving radially.

The following achievement has been made:

1. The parted pulley construction has been designed in the new way.

2. The construction is simple, the cost is low and the application is wide.

3. The pressing force acting on the side of transmission belt is eliminated when regulating speed, hereby, the wear is greatly reduced.

4. Summarized split CVT V-belt drive of the effective Circumference force method of calculating.

Key words: belt-type transmission; continuously variable transmission (CVT); parted pul

前言 1

1 机械无级变速器的概况 4

1.1 分类及应用 4

1.2 国内外研究情况 5

1.3 带式无级变速器的特点及存在的问题 7

1.4 课程设计内容及意义 10

1.4.1 设计任务 10

1.4.2 设计内容 10

2 小功率微型电动轿车无级变速器工作原理 11

2.1 方案分析 11

2.2 结构组成 11

2.3 工作原理 13

2.4 主要性能参数 13

2.4.1 传动比 13

2.4.2 变速比带 14

2.4.3 滑动率 14

3 分体带轮及锥体的设计 15

3.1 带传动参数计算 15

3.2 锥体及分体设计 16

3.3 带传动计算 18

3.4 带轮结构 24

4 轴及轴承的设计 26

4.1 轴的初设计 26

4.2 主要轴承选用与校核 27

4.3 轴向尺寸确定 29

4.4 轴的校核 29

4.4.1 按弯扭合成强度条件校核轴的强度 29

4.4.2 按疲劳强度计算危险截面的安全系数 32

4.4.3 静强度安全系数校核 33

4.4.4 轴的刚度校核 34

4.5 键强度校核 37

4.5.1 花键强度校核 37

4.5.2 输入输出平键强度校核 38

4.6 分体式V带传动无级变速器的有效拉力计算 39

4.7 汽车驱动力与行驶速度校核 42

5 调速机构设计 44

5.1 调速机构综述 44

5.2 液压机构设计 45

5.2.1 液压缸的设计计算 46

5.2.2 速度输出曲线 49

结 论 50

致 谢 51

参考文献 52

…………