毕业设计辅助工具_免费论文文案文章修改神器_毕业设计辅助软件_论文查重...¥0

毕业设计辅助工具_免费论文文案文章修改神器_毕业设计辅助软件_论文查重...¥0 solidworks2018 中文版¥0

solidworks2018 中文版¥0 CA6140车床拨叉831006零件夹具设计说明书——9页...¥0

CA6140车床拨叉831006零件夹具设计说明书——9页...¥0 机械设计制造及其自动化毕业设计(论文)开题报告...¥0

机械设计制造及其自动化毕业设计(论文)开题报告...¥0 XX大学理工类毕业设计(论文)开题报告——自行车配件管理系统...¥0

XX大学理工类毕业设计(论文)开题报告——自行车配件管理系统...¥0 课程设计 CA6140车床拨叉831002的加工工艺及钻φ25孔的钻床...¥0

课程设计 CA6140车床拨叉831002的加工工艺及钻φ25孔的钻床...¥0 陈家沟桥梁施工组织设计方案.doc...¥0

陈家沟桥梁施工组织设计方案.doc...¥0 毕业设计辅助工具_免费在线论文文案文章修改神器_毕业设计辅助软件_AI...¥0

毕业设计辅助工具_免费在线论文文案文章修改神器_毕业设计辅助软件_AI...¥0 六自由度工业机器人设计【说明书(论文)+CAD图纸+SolidWork...¥45.00

六自由度工业机器人设计【说明书(论文)+CAD图纸+SolidWork...¥45.00 Solidworks2016¥0

Solidworks2016¥0摘 要

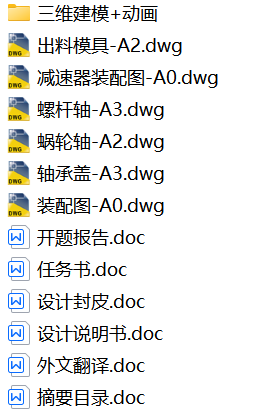

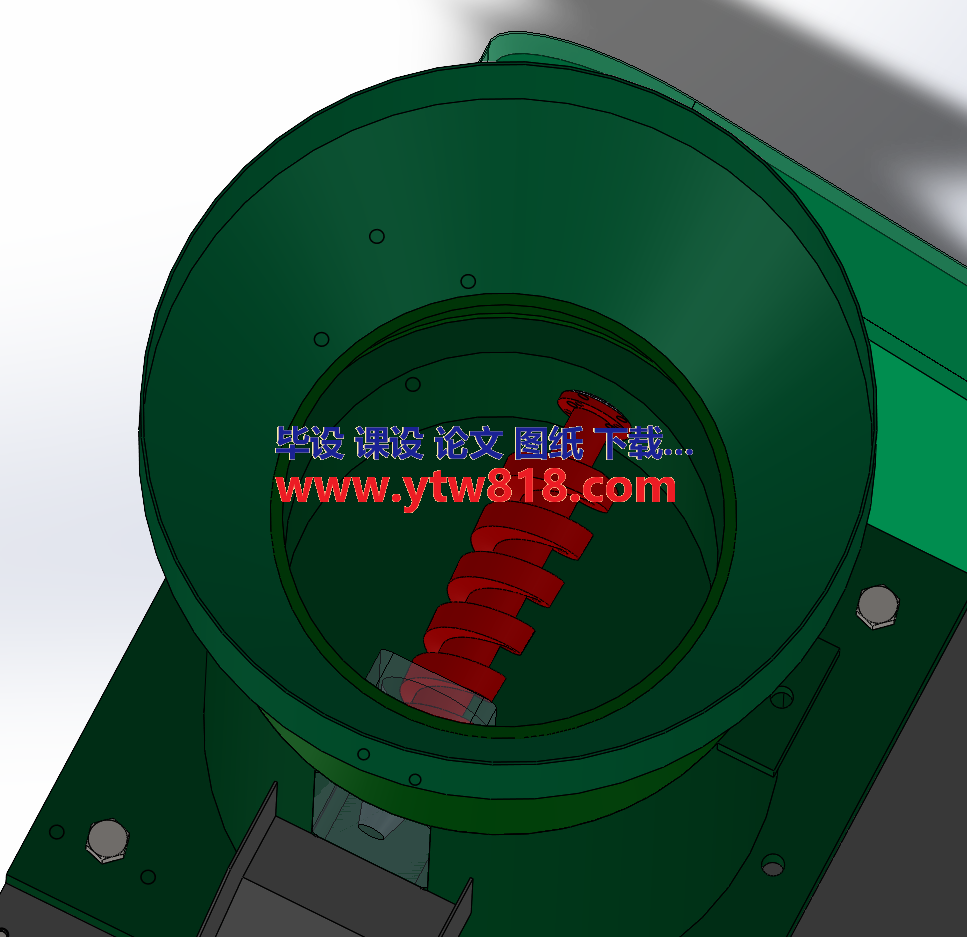

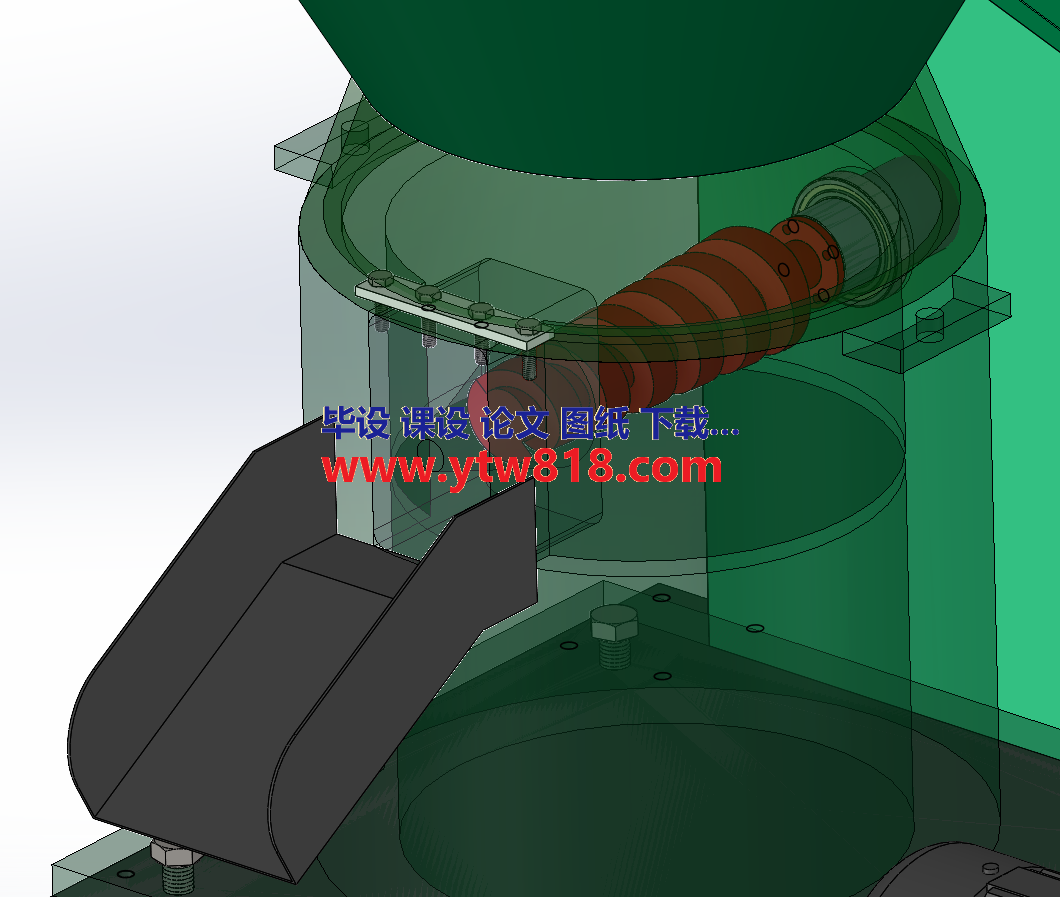

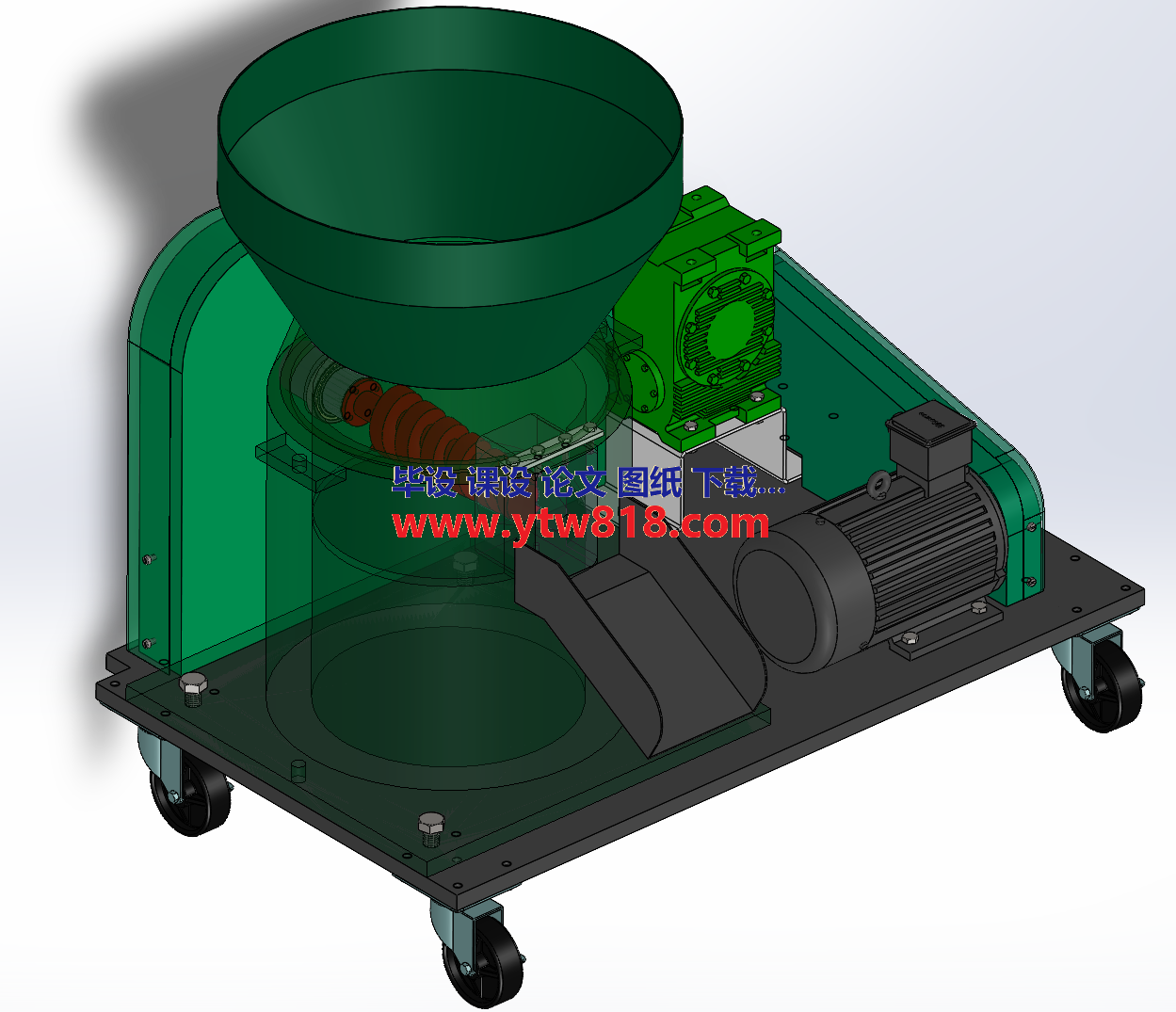

通常利用农作物秸秆颗粒成型技术,把那些松散细碎或者无定型的秸秆挤压成为形状规则且又质地紧密的成型燃料,这统称为秸秆压缩。当秸秆挤压成为颗粒后,它的能量密度大幅提升,燃烧特性会较成型之前有大幅改善。秸秆批量生产的重点是有性能优越的秸秆压缩机。首先,秸秆压缩的产量主要由秸秆成型机的颗粒效率决定。再者,压缩成本的增高是由成型机能耗过多造成的。因此,秸秆颗粒成型行业的首要课题是新型秸秆成型技术和设备的研究和发展。本文的设计内容为研究秸秆颗粒成型机在国内外应用的现状。根据研究结果,仔细分析比较现有的颗粒成型机,采纳不同结构的优点,再设计成型机的最佳方案。确定最佳设计方案后,对重要部件如:轴承、电动机、减速器、连接轴等进行计算并选型,再对其进行应力校核。运用Solidworks对秸秆颗粒成型机进行三维建模是本次工作的最后一步。本次设计的农作物秸秆颗粒成型机体积小,能使废弃的资源得到合理利用并能创造经济利益,而且操作非常简单,能够更多的运用到日常生活中,最后他的维护成本也是极低的。

关键词 秸秆;螺旋式;结构设计;复杂性

Structure Design of Grain Forming Machine Straw

Abstract

. Usually the use of crop straw particle molding technology, those loose or broken straw or extruded into a regular shape and compact texture of the molding of fuel, which collectively referred to as straw compression. When the straw is extruded into particles, its energy density is greatly improved, and the combustion characteristics are significantly improved before molding.. First, the yield of straw compression is determined primarily by the particle efficiency of the straw molding machine.Therefore, the straw pellet molding industry's top priority is the new straw molding technology and equipment research and development. The design of this paper is to study the application status of straw granulator at home and abroad. According to the results of the study, careful analysis of the existing particle molding machine, the advantages of different structures, and then design the best molding machine. Determine the best design, the important parts such as: bearings, motors, reducer, connecting shaft, etc. to calculate and select, and then its stress check. The use of Solidworks on the straw particle molding machine for three-dimensional modeling is the last step in this work. The design of the crop straw particle molding machine small size, can make the waste of resources to be rational use and can create economic benefits, and the operation is very simple, can be more applied to daily life, and finally his maintenance costs are very low.

Keywords Straw,screw type,the structuredesign,complexity

目 录

摘要 I

Abstract II

………………